All you need to know about QD bush manufacturer in India

When industries move, the machines behind them must move with precision. Whether it is automotive production, textile machinery, conveyor systems, or power transmission setups, the need for well-engineered components is constant. Among these, the QD bush plays a quietly vital role in ensuring that rotating equipment functions seamlessly. A QD (quick detachable) bushing is engineered to offer a firm grip on shafts while still allowing simple removal and repositioning. Over time, this component has become indispensable to industries that value minimal downtime and dependable performance. In India, one name that has built a reputation through consistency, engineering focus, and technical precision is Aashapuri Engineering Pvt. Ltd. As a leading QD bush manufacturer in India, Aashapuri Engineering has positioned itself at the intersection of traditional workmanship and evolving industrial requirements. The company understands that a QD bushing is not just a passive metal sleeve but a vital link in any rotating system. By combining durability, dimensional accuracy, and adaptability, Aashapuri Engineering supplies products that support some of the most demanding industrial environments. This blog explores not only what a QD bush is, but also how manufacturers like Aashapuri Engineering has refined its design, functionality, and role in advanced applications, especially in relation to the timing pulley manufacturer in India.

Understanding the Role of QD Bushings in Industrial Machinery

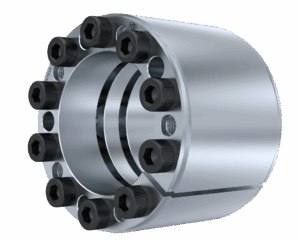

A QD bushing is more than just a hub component—it is a mechanical connector that merges rotating shafts with pulleys, sprockets, and gears. What makes it uniquely valuable is its tapered construction, which allows it to self-lock onto shafts while simultaneously offering quick detachment. This smart geometry ensures torque transmission and reduces maintenance hassle during machinery repairs or upgrades.

The conventional challenges industries face in power transmission systems often revolve around slippage, wear, and misalignment. QD bushings effectively address these issues by creating a concentric grip on the shaft. The split-through flange and keyless design mean these bushings can be installed and removed without damaging the shaft or the driven component. As a result, industries experience less unplanned downtime, smoother operation, and improved equipment life.

In a fast-paced manufacturing setup where every minute of downtime leads to significant costs, the functionality of a well-designed QD bush becomes indispensable. Its efficiency becomes even more pronounced when used in systems that require frequent part replacement or precise alignment, such as automated conveyor belts or high-speed textile looms.

Evolution of QD Bush Design and the Indian Manufacturing Landscape

India’s rise as a manufacturing powerhouse has not happened overnight. Over the past few decades, the country has moved from merely assembling products to engineering key components that power global industries. The QD bush is one such example of how Indian manufacturers have mastered mechanical design.

Traditional bush systems required longer downtime during replacements or adjustments, often involving specialized tools or machining. With the rise of quick-detachable technology, manufacturers in India began engineering bushings that combine easy installation with performance reliability. Aashapuri Engineering Pvt Ltd has been a part of this transformation, bringing precision metallurgy and design standards into the production of QD bushes.

Their facilities integrate advanced measurement tools, quality assurance frameworks, and a profound understanding of power transmission needs. Unlike generic suppliers, Aashapuri Engineering has built a focused reputation around developing solutions that cater specifically to industries requiring torque resilience, high-speed alignment, and dimensional compatibility.

Material Quality and Engineering Standards in QD Bush Production

At the heart of every reliable QD bush is the material from which it is manufactured. The metallurgy plays a crucial role in determining the bush’s strength, resistance to wear, and capacity to withstand temperature or corrosive conditions.

Aashapuri Engineering Pvt Ltd works with carefully selected grades of steel and cast iron, ensuring that every batch meets strict quality criteria. Each QD bush undergoes heat treatment processes designed to enhance its toughness while preserving dimensional integrity. This feature is essential in high-speed applications where even minor inaccuracies can lead to misalignment or premature wear.

Additionally, the surface finish of a QD bushing affects its grip and wear resistance. The smoother the finish, the better the contact between the shaft and the driven part. Aashapuri Engineering focuses on this level of detail, offering QD bushings that deliver lasting performance without compromise. The company’s stringent inspections also ensure that each unit meets not only Indian standards but also aligns with international expectations, making it a trusted name in export markets.

Importance of Compatibility with Timing Pulleys

While standalone QD bushings serve numerous mechanical purposes, their true value is often highlighted when paired with timing pulleys. A timing pulley system ensures synchronous movement of machine parts without slippage, which is vital in operations requiring precise sequencing.

When QD bushings are engineered to be compatible with timing pulleys, they allow for easy installation and realignment of pulley systems during maintenance cycles. This capability is particularly useful in industries like printing, packaging, and automation, where even millimetre-level timing deviations can impact the final product quality.

Aashapuri Engineering Pvt Ltd has understood this synergy. As a QD bush with a timing pulley manufacturer in India, the company offers integrated solutions where both components are optimized to work together. The result is reduced maintenance time, enhanced machine synchronization, and improved lifespan of rotating systems.

Applications Across Industrial Sectors

The range of applications for QD bushings is vast. They are found in agricultural machinery, construction equipment, textile mills, food processing lines, material handling systems, and even mining operations. Each of these sectors demands durability and dependability from its mechanical components, and QD meets these challenges.

A QD bushing in agricultural equipment must provide secure engagement without slippage, even in dusty environments with unpredictable loads. In textile mills, where speed and accuracy govern production, the bush must offer fine tolerance and vibration damping. In mining, where equipment must withstand high shock loads, the metallurgy and locking mechanism of the bush become even more critical.

Aashapuri Engineering addresses these sector-specific needs by offering QD bushings in varied sizes, finishes, and material compositions. Their engineering team works closely with industry requirements to develop designs that are both application-specific and scalable.

Manufacturing Precision and Customization Capabilities

One of the most important qualities of a reliable QD bushing manufacturer is the ability to customize components to meet unique requirements. Aashapuri Engineering has built a reputation for manufacturing QD bushes not only as per standard catalogue specifications but also as per custom drawings and special dimension requests.

This flexibility is critical in sectors where standard sizes may not align with the original equipment or when upgrades involve machines from international brands with non-standard specifications. Aashapuri Engineering’s in-house design and machining capabilities ensure that such needs are met with accuracy and speed.

Each custom QD bush undergoes dimensional analysis, stress testing, and performance verification before dispatch. This process ensures that the end product meets the precise torque, fitment, and alignment demands of the intended application. This customer-centric focus is what differentiates Aashapuri Engineering from generic component suppliers.

Export Focus and Global Reach

Indian manufacturers are increasingly taking center stage in the global component supply chain, and Aashapuri Engineering Pvt Ltd is no exception. With a portfolio that meets international quality standards, the company serves not only domestic industries but also clients across Europe, the Middle East, Southeast Asia, and Africa.

This export-ready approach includes multilingual documentation, standardization compliance, and logistics management that makes international trade seamless. Their QD bushes are engineered to meet ISO and DIN benchmarks, giving confidence to global clients who require repeatable quality and dependable delivery schedules.

The global growth of Aashapuri Engineering also reflects the trust it has earned among international OEMs and distributors, who value a dependable Indian partner for high-quality mechanical parts.

The Role of Testing, Certification, and Quality Assurance

A key reason why Aashapuri Engineering continues to thrive in a competitive marketplace is its unwavering focus on quality control. Each QD bushing undergoes a series of quality checks, including hardness testing, dimension checks using CMMs (Coordinate Measuring Machines), run-out tests, and visual inspection for casting integrity.

These tests are not just procedural—they form the backbone of the company’s reputation. The goal is not simply to manufacture parts but to engineer reliability. In an industry where failure of a single component can halt an entire production line; quality assurance becomes not just a metric but a philosophy.

Moreover, the company consistently invests in certifications that validate its practices and instill confidence in its buyers. From ISO certification to performance validation by third-party agencies, every standard is pursued with diligence.

Sustainability in Manufacturing Practices

In an age where sustainability is no longer optional, manufacturers like Aashapuri Engineering are embracing processes that minimize waste, optimize energy use, and reduce environmental impact. This strategy includes the adoption of recycled metal where permissible, implementation of machining processes that lower scrap generation, and reuse of machining fluids and lubricants.

The factory layout and workflow have been optimized to ensure efficient material handling, which reduces power consumption and enhances throughput. These efforts are not just ethical; they also add economic value by reducing overhead, improving resource utilization, and ultimately benefiting the customer.

Vision for the Future of QD Bush Manufacturing in India

The future of QD bush manufacturing lies in the integration of smart manufacturing techniques. While mechanical parts may not seem like candidates for digital innovation, technologies like CAD-driven design, CNC automation, and real-time quality analytics are already shaping the next era.

Aashapuri Engineering is preparing for this transition by investing in digital design platforms, upgrading machinery, and training its workforce in predictive quality control methods. The vision is not only to supply components but to become partners in industrial growth—contributing to India’s identity as a global manufacturing hub.

By combining traditional mechanical expertise with forward-looking processes, Aashapuri Engineering aims to remain at the forefront of this transformation.

Summary

In conclusion, the story of the QD bush is not merely about a mechanical part—it is about the silent reliability behind rotating systems across industries. Its tapered design, easy installation, and torque-handling abilities have made it a core component in modern mechanical setups. As one of the most trusted names in the business, Aashapuri Engineering Pvt Ltd has established itself as a top QD bush manufacturer in India, delivering consistency, quality, and customization with every unit.

Our capabilities as a QD bush and timing pulley manufacturer in India further demonstrate their commitment to offering complete solutions to industrial challenges. By aligning their production with global standards, investing in sustainable practices, and focusing on continuous improvement, Aashapuri Engineering not only meets the needs of today’s industries but also prepares for the requirements of tomorrow.

To learn more about how Aashapuri Engineering Pvt Ltd can support your next industrial project with precision-crafted QD bushes, contact our team today and discover a new level of engineering reliability.