Boosting Efficiency: How Upgraded Parts Can Save Energy

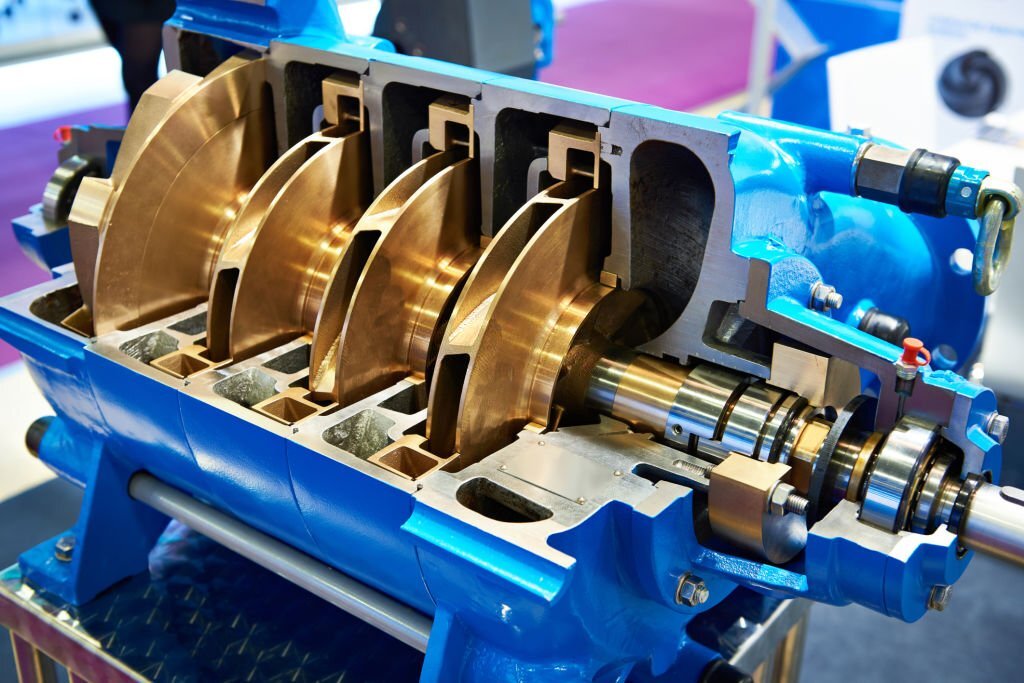

In today’s fast-paced industrial landscape, optimizing energy usage is not just a goal but a necessity. As industries strive to reduce their carbon footprint and operational costs, one area that holds immense potential for improvement is the efficiency of centrifugal compressors. These vital components are ubiquitous in various sectors, from manufacturing to petrochemicals, playing a crucial role in processes such as air conditioning, refrigeration, and gas compression.

At the heart of every centrifugal compressor lie its parts – the components that dictate its performance, reliability, and energy consumption. Upgrading these parts can yield significant benefits in terms of energy efficiency, productivity, and sustainability. Aashapuri, a leading centrifugal compressor parts manufacturer in India, is at the forefront of this paradigm shift, offering cutting-edge solutions tailored to the needs of the Indian market.

Understanding Centrifugal Compressor Efficiency

Before delving into the specifics of upgraded parts, it’s essential to grasp the concept of compressor efficiency. Efficiency in centrifugal compressors is typically measured by two key parameters: isentropic efficiency and mechanical efficiency.

Isentropic efficiency refers to the compressor’s ability to compress air or gas without incurring energy losses due to friction or heat transfer. It represents the ratio of the actual compression work to the ideal work input under reversible adiabatic conditions. Mechanical efficiency, on the other hand, accounts for losses associated with bearings, seals, and other mechanical components.

The Impact of Upgraded Parts

Upgrading centrifugal compressor parts can have a transformative impact on both isentropic and mechanical efficiency. Aashapuri specializes in manufacturing precision-engineered parts that address common inefficiencies and performance limitations. Here’s how these upgrades contribute to energy savings and enhanced performance:

- Advanced Impellers and Diffusers: The impeller and diffuser are critical components that determine the compressor’s aerodynamic performance. By incorporating advanced design features and utilizing high-performance materials, Aashapuri’s upgraded impellers and diffusers minimize losses due to turbulence and flow separation, thereby improving isentropic efficiency.

- Efficient Bearings and Seals: Bearings and seals play a crucial role in minimizing mechanical losses and ensuring smooth operation. Aashapuri’s upgraded bearings utilize advanced materials and lubrication systems to reduce friction and wear, enhancing mechanical efficiency and extending component life.

- Optimized Control Systems: In addition to physical components, control systems also play a significant role in compressor efficiency. Aashapuri offers state-of-the-art control solutions that optimize compressor operation based on real-time demand, ensuring that energy consumption is aligned with process requirements.

Sustainable Solutions for the Indian Market

As a prominent centrifugal compressor parts manufacturer in India, Aashapuri understands the unique challenges and opportunities presented by the Indian industrial landscape. With a focus on sustainability and cost-effectiveness, Aashapuri’s upgraded parts are tailored to meet the specific needs of Indian industries, including:

- Adaptability to Variable Operating Conditions: Indian industries often face fluctuating demand and operating conditions. Aashapuri’s upgraded parts are designed to perform reliably across a wide range of operating parameters, ensuring consistent efficiency and productivity.

- Compatibility with Existing Infrastructure: Retrofitting existing compressors with upgraded parts is a cost-effective way to enhance efficiency without the need for major capital investments. Aashapuri provides retrofit solutions that seamlessly integrate with existing compressor systems, minimizing downtime and maximizing returns.

- Local Support and Expertise: With a strong presence across India, Aashapuri offers local support and expertise to assist customers in optimizing their compressor performance. From installation and commissioning to maintenance and troubleshooting, Aashapuri’s team of experts is committed to delivering unparalleled service and support.

Conclusion

In conclusion, upgrading centrifugal compressor parts offers a promising pathway towards boosting energy efficiency, reducing operating costs, and enhancing sustainability. As a trusted centrifugal compressor parts manufacturer in India, Aashapuri is dedicated to providing innovative solutions that empower industries to achieve their efficiency goals while driving positive environmental impact. By embracing the latest advancements in compressor technology and engineering, Aashapuri is leading the charge towards a more efficient and sustainable future for Indian industries.

For inquiries about Aashapuri’s upgraded centrifugal compressor parts and solutions, visit https://aashapuriengg.com/ or contact our team directly. Let’s embark on a journey towards greater efficiency and sustainability together.