Common Problems in Centrifugal Pump Parts and How Indian Manufacturers Fix Them

Centrifugal pumps are like the superheroes of the industrial world. They help move liquids by spinning really fast, which turns the energy into a force that pushes the liquid through pipes. But just like superheroes need a good costume to work properly, centrifugal pumps need all their parts in good shape to do their job well. Sometimes, these parts can run into problems, but don’t worry! Indian manufacturers, like Aashapuri Engineering Pvt Ltd, have figured out how to fix these issues and keep the pumps running smoothly. Let’s explore some common problems with centrifugal pump parts and see how they’re addressed, in a way that’s easy to understand.

1. Centrifugal Pump Plugs: Keeping the Flow Under Control

Think of the centrifugal pump plug as a superhero’s shield. It helps control the flow of liquids, making sure everything moves in the right direction. But over time, this shield can get a bit worn out.

- Common Problems:

- The plug might get scratched or damaged from lots of use, kind of like how your favorite toy might get a little worn out if you play with it too much.

- Sometimes, if the liquid is like a supervillain (harsh chemicals), it can attack the plug and make it rusty or weak.

- If the plug isn’t put in just right, it might not stop leaks, letting some of the liquid escape.

- Solutions by Indian Manufacturers:

- To make the plug strong, manufacturers use materials like stainless steel, which is like armor that doesn’t rust easily.

- They use super-precise tools to make sure the plug fits perfectly, stopping any sneaky leaks.

- Before sending out the plugs, they check them carefully to make sure they work just right.

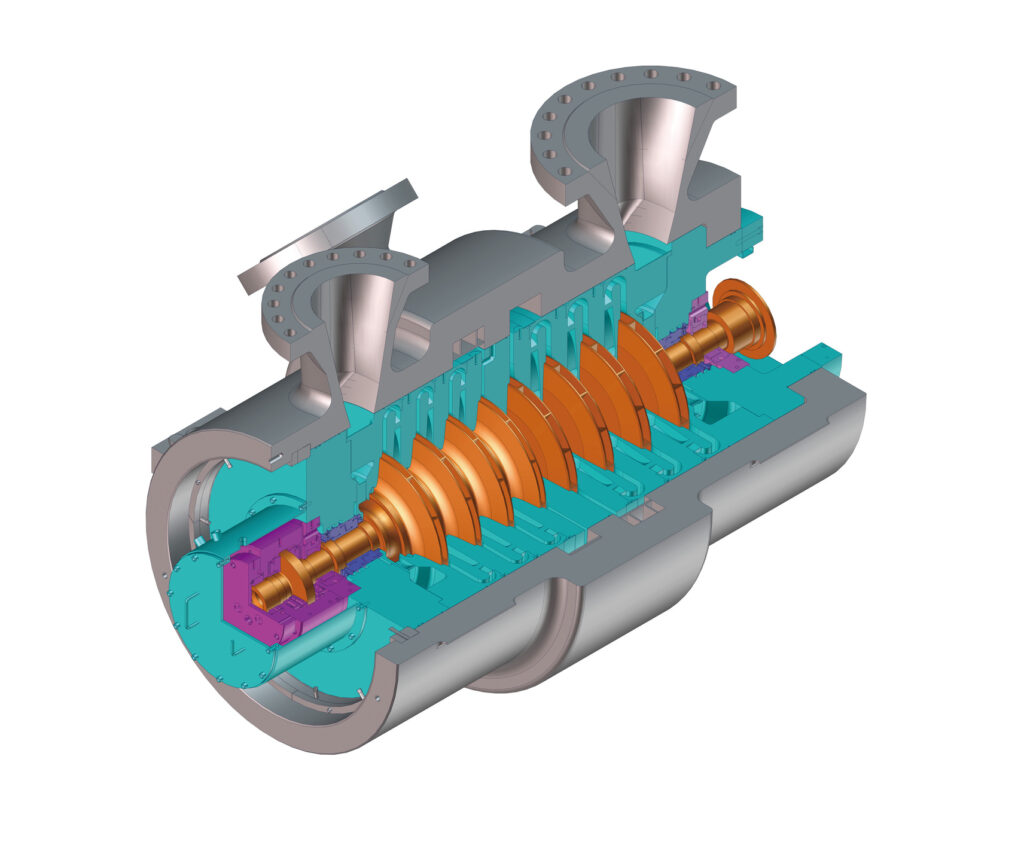

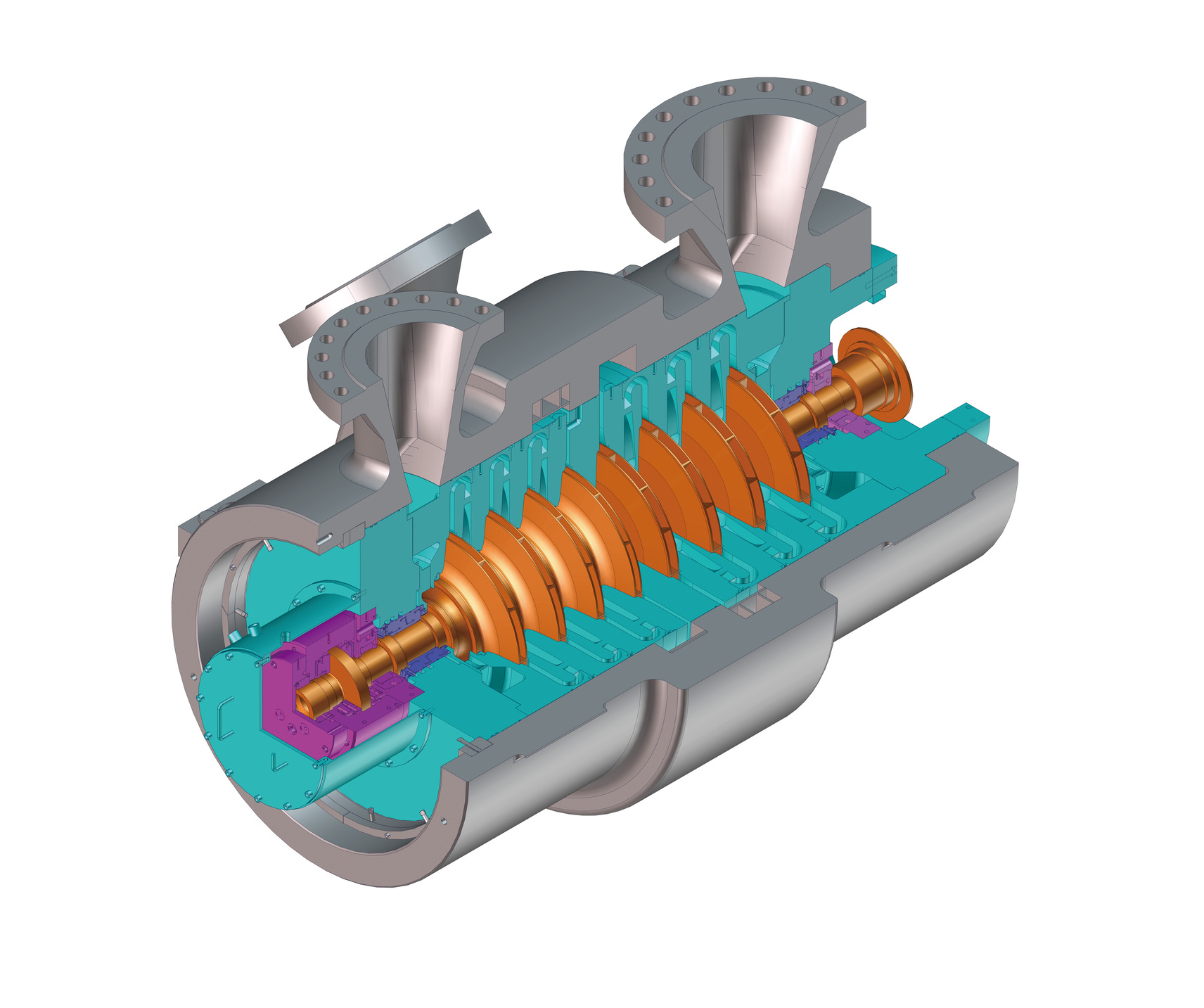

2. Centrifugal Compressor Parts: Keeping Everything in Balance

Centrifugal compressors help squeeze gases together, kind of like how you might squeeze toothpaste out of a tube. But if the parts inside aren’t working well, things can get wobbly.

- Common Problems:

- The compressor can shake or vibrate too much, which can wear out the parts, just like a bike might get wobbly if the wheels aren’t tight.

- Bearings inside the compressor can wear out if they don’t get enough oil, like how a squeaky door needs oil to open smoothly.

- If the parts aren’t lined up right, it can cause the compressor to work less efficiently, like trying to ride a bike with misaligned wheels.

- Solutions by Indian Manufacturers:

- Indian manufacturers balance the parts perfectly to stop them from shaking.

- They use good lubrication to keep the bearings running smoothly, just like putting oil on a squeaky door.

- They check and double-check that everything is lined up correctly, making sure the compressor works like a charm.

3. Centrifugal Pump Bearing Covers: Protecting the Bearings

The bearing cover is like a protective shield for the bearings inside the pump, keeping them safe from dust, dirt, and other bad stuff.

- Common Problems:

- Sometimes, dirt or water can sneak in and damage the bearings, just like mud can ruin a clean pair of shoes.

- If the cover isn’t put on right, it can wear out quickly.

- The cover might crack if the pump is under too much pressure, like how a balloon might pop if you blow it up too much.

- Solutions by Indian Manufacturers:

- They use strong, durable materials to make the covers, so they don’t break easily.

- They make sure the covers fit perfectly, keeping the dirt and water out.

- Special seals are used to add extra protection, like putting a raincoat on to stay dry.

4. Centrifugal Pump Casings: The Outer Armor

The casing of a centrifugal pump is like the superhero’s suit, protecting all the important parts inside.

- Common Problems:

- If the pump handles corrosive liquids, the casing can start to corrode, like how metal can rust in the rain.

- Pressure surges can cause the casing to crack, like a superhero suit tearing under stress.

- If there are tiny, sharp particles in the liquid, they can erode the casing, wearing it down over time.

- Solutions by Indian Manufacturers:

- They use special metals that resist corrosion, like how some metals don’t rust even when they get wet.

- For high-pressure situations, they make the casing thicker and stronger.

- They also use special coatings to protect the casing from wear and tear, like putting a protective layer on your phone screen.

5. Centrifugal Pump Shaft Sleeves: The Unsung Heroes

The shaft sleeve is like a protective layer for the pump’s shaft, keeping it from getting worn out or damaged.

- Common Problems:

- Friction can cause the sleeve to wear down, like how your shoes can get worn out if you walk a lot.

- Corrosive liquids can attack the sleeve, making it weaker.

- If the sleeve isn’t put on properly, it can cause the pump to not work right.

- Solutions by Indian Manufacturers:

- They use tough materials like hardened steel or even ceramic coatings, which are super strong.

- They make sure the sleeves are made to fit perfectly, so they protect the shaft properly.

- Regular checks help catch any problems early, so the sleeves can be replaced before they cause trouble.

How Indian Manufacturers Ensure Quality

Indian manufacturers, like Aashapuri Engineering Pvt Ltd, are really good at making sure all these parts work well together. They do this by:

- Choosing the Right Materials: They pick materials that can handle tough conditions, so the parts last a long time.

- Precision Engineering: They use advanced machines to make sure every part fits just right.

- Quality Control: Before the parts leave the factory, they’re tested to make sure they’re perfect.

- Customer Support: They help customers with any questions or problems, making sure the pumps keep running smoothly.

- Innovation: They’re always looking for new ways to make the parts even better, keeping up with the latest technology.

Conclusion

Centrifugal pumps might seem complicated, but with the right care and quality parts, they can work like a superhero team, keeping everything running smoothly. Indian manufacturers, like Aashapuri Engineering Pvt Ltd, are experts at making sure these pumps stay in top shape. Whether it’s a Centrifugal Pump plug, bearing cover, casing, or shaft sleeve, they have the tools and knowledge to fix any problem. By using strong materials, precision engineering, and careful testing, they ensure that every part of the pump is ready to do its job. So, next time you think of a centrifugal pump, remember the team of parts working together to keep things moving.