Easy Guide to Making Volute and Diffuser Casings in India

Volute and diffuser casings are important parts of pumps that help move water and other liquids. Pumps are used in many places, like water treatment plants and oil refineries. In India, companies are using new ways to make these casings. Let’s learn about how these parts are made, especially by a company called Aashapuri Engineering Pvt Ltd.

What Are Volute and Diffuser Casings?

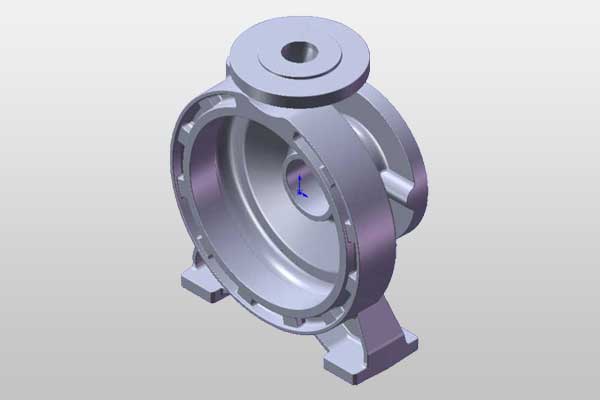

Imagine a pump is like a big straw that moves water. The volute casing is like a special shell around the straw that helps push the water out smoothly and with more force. The diffuser casing helps calm the water down and stops it from swirling too much, making everything work better.

How Are They Made?

To make these casings, factories use a method called casting. First, they make a model of the casing using wax. Then, they cover this model in a ceramic shell. After that, they melt the wax away, leaving an empty shell. They pour hot, liquid metal into this shell, and when it cools, they break the shell to get the metal casing.

Making Sure They Are Just Right

Once the casing is made, it needs to be shaped perfectly. This is done using special machines that are controlled by computers. These machines cut and smooth the casings so they fit perfectly with other parts of the pump.

Making Them Strong and Shiny

The casings are then heated and cooled to make them stronger. This process helps them last longer and not wear out quickly. After that, they polish the casings to make them shiny and protect them from rust.

Customizing for Special Needs

Sometimes, people need casings of different sizes or shapes for different pumps. Indian companies can make these customized casings to meet specific needs. This is like ordering a pizza with your favorite toppings!

Being Good to the Earth

Many companies in India try to be kind to the environment. They use recycled materials and try to produce less waste. This not only helps the planet but also saves money.

Checking Quality

To make sure the casings are high quality, they go through many tests. These tests check if the casings are the right size, if they can handle pressure, and if there are any cracks or defects. This is like a final exam to make sure everything is perfect.

Why Certification Matters

Certification is like getting a gold star that shows the casings are well-made and safe to use. Many companies in India, like Aashapuri Engineering Pvt Ltd, have these certifications. This makes customers feel confident about buying their products.

The Future of Casing Manufacturing in India

The future looks bright for making volute and diffuser casings in India. Companies are always looking for new ways to make their products better. For example, they might start using 3D printing to make casings faster and more accurately.

Working Together

Indian companies often work together with other companies and experts to learn new things and improve their products. This teamwork helps them stay ahead in the global market.

Facing Challenges and Finding Opportunities

There are some challenges, like the changing prices of materials and the need for skilled workers. But these challenges also bring new opportunities. For instance, using robots and new technologies can help make things more efficient and save costs.

Conclusion

In summary, India is becoming a leader in making volute and diffuser casings, thanks to new manufacturing techniques and a focus on quality. Companies like Aashapuri Engineering Pvt Ltd offer high-quality, customized products that are important for many industries. With a commitment to innovation and teamwork, the future of this industry in India looks very promising.

Whether you’re looking for a Centrifugal Volute Casing Manufacturer in India or any other related components, Indian manufacturers have a lot to offer. They are dedicated to making reliable products that help in various industrial applications, making them a key player in the global market.