Eco-Friendly Practices in Centrifugal Pump Parts Manufacturing in India

In today’s world, being environmentally friendly is more important than ever, especially in industries like manufacturing, which can significantly impact our planet. In India, companies like Aashapuri Engineering Pvt Ltd are leading the way in using eco-friendly practices to make centrifugal pump parts. This article explores how these companies are making a difference and why it matters.

What Are Centrifugal Pumps and Their Parts?

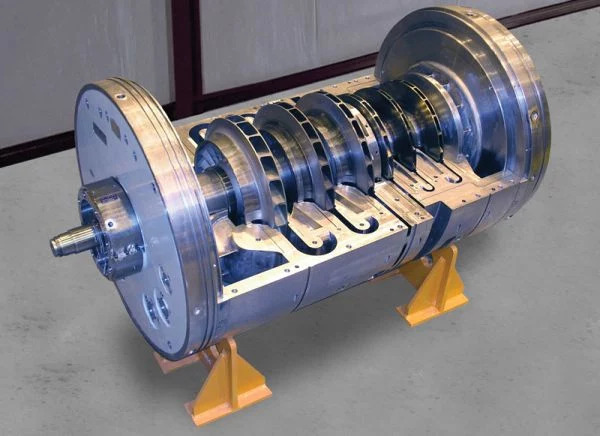

Centrifugal pumps are commonly used in industries like water supply, wastewater treatment, and chemical processing. These pumps work by turning the energy from a motor into energy that moves a fluid. Key parts of centrifugal pumps include:

- Pump Casing: The outer shell that holds the fluid and guides it through the pump.

- Impeller: A spinning part that gives the fluid its energy.

- Shaft Sleeve: A protective covering that shields the shaft from damage.

- Bearing Cover: A part that houses and protects the bearings, helping the pump run smoothly.

- Pump Plug: A component used to seal and control the flow of fluids.

Aashapuri Engineering Pvt Ltd, a well-known centrifugal pump parts manufacturer in India, produces these crucial components, ensuring they are high-quality and long-lasting. Now, let’s look at the eco-friendly practices these companies are using in manufacturing these parts.

Using Eco-Friendly Materials and Processes

A significant step towards eco-friendly manufacturing is using sustainable materials. Aashapuri Engineering Pvt Ltd, a leading centrifugal pump plug manufacturer in India, has started using materials that are both durable and environmentally friendly. This includes recycled metals and biodegradable materials, which help reduce their carbon footprint.

In addition to materials, the manufacturing processes are essential. For example, advanced machining techniques minimize waste. This precision in manufacturing ensures that every piece of material is used efficiently, reducing waste and conserving resources.

Saving Energy in Manufacturing

Energy consumption is a major issue in manufacturing. To tackle this, companies like Aashapuri Engineering Pvt Ltd invest in energy-efficient machinery and technologies. By optimizing energy use in producing centrifugal pump casing and other parts, these companies can significantly reduce their environmental impact.

Moreover, many manufacturers are now using renewable energy sources, like solar and wind power, in their operations. This shift not only reduces the reliance on fossil fuels but also promotes sustainability in the industry.

Water Conservation

Water is an essential resource in manufacturing, particularly for cooling and cleaning. Manufacturers in India are adopting water-saving technologies. For instance, Aashapuri Engineering Pvt Ltd, known for its centrifugal pump bearing cover manufacturing, uses systems that recycle water, significantly cutting down on fresh water usage.

Moreover, wastewater treatment plants are being set up within manufacturing facilities. These plants treat and reuse wastewater, ensuring harmful pollutants do not enter the environment. This practice not only saves water but also protects local ecosystems.

Managing and Recycling Waste

Effective waste management is another critical aspect of eco-friendly manufacturing. In the production of centrifugal pump shaft sleeves and other parts, waste materials can include metals, plastics, and chemicals. Companies are now focusing on recycling these materials wherever possible.

Aashapuri Engineering Pvt Ltd, a leader in centrifugal pump parts manufacturing in India, has robust waste management systems. Scrap metals are collected and sent to recycling facilities, while non-recyclable waste is disposed of responsibly. This reduces the strain on landfills and conserves natural resources.

Reducing Emissions

Manufacturing processes can release pollutants and greenhouse gases into the air. To combat this, many companies are investing in technologies to control emissions. For example, Aashapuri Engineering Pvt Ltd has installed advanced filtration systems in its factories to capture harmful particles and gases.

Moreover, adopting cleaner technologies, such as electric furnaces and low-emission machinery, helps reduce overall emissions from manufacturing. These steps are crucial in reducing the environmental impact of industrial activities.

Employee Training and Safety

Eco-friendly practices are not just about technology and processes; they also involve people. Training employees on environmental awareness and safety is essential. Aashapuri Engineering Pvt Ltd regularly trains its staff on sustainable practices and the proper handling of materials.

Ensuring a safe working environment is also a priority. This includes measures to protect employees from hazardous substances and ensure that waste disposal practices do not pose health risks. A safe and knowledgeable workforce is a key component of sustainable manufacturing.

Community Engagement and Corporate Social Responsibility

Companies like Aashapuri Engineering Pvt Ltd understand the importance of involving the community in their sustainability efforts. By engaging local communities in environmental initiatives, these companies foster a culture of sustainability beyond their factories.

Corporate Social Responsibility (CSR) programs often include activities like tree planting, community clean-up drives, and environmental education campaigns. These initiatives benefit the environment and strengthen the company’s relationship with the community.

Challenges and the Future

While significant progress has been made, there are still challenges in achieving complete sustainability in manufacturing. One of the main hurdles is the initial cost of implementing eco-friendly technologies. However, many companies find that the long-term savings and benefits outweigh these initial investments.

Additionally, there is a need for stricter regulations and standards to guide and enforce sustainable practices in the industry. Government support, such as incentives and subsidies, can also encourage more companies to adopt green technologies.

The Role of Consumers

Consumers also play a vital role in promoting eco-friendly manufacturing. By choosing products from companies that prioritize sustainability, consumers can drive demand for greener products. This, in turn, encourages more companies to adopt eco-friendly practices.

Aashapuri Engineering Pvt Ltd, a responsible centrifugal pump parts manufacturer in India, is committed to educating its customers about the importance of sustainability. By highlighting their eco-friendly practices, they not only differentiate themselves in the market but also contribute to a larger movement towards sustainable industry practices.

Conclusion

Eco-friendly practices in centrifugal pump parts manufacturing are not just a trend but a necessity for the future. Companies like Aashapuri Engineering Pvt Ltd are leading the way by implementing sustainable practices in their production processes. From using eco-friendly materials to investing in energy-efficient technologies and engaging with the community, these companies are making a significant impact.

As the demand for sustainable products continues to grow, it is crucial for manufacturers to prioritize eco-friendly practices. By doing so, they not only protect the environment but also ensure a sustainable future for the industry and the communities they serve.

In conclusion, the journey towards sustainable manufacturing is ongoing. It requires continuous innovation, collaboration, and commitment from all stakeholders, including manufacturers, consumers, and governments. Together, we can build a more sustainable and environmentally responsible future for the manufacturing industry.