Exploring the Various Parts of a Centrifugal Pump

Centrifugal pumps are indispensable in a wide range of industries, playing a crucial role in transporting fluids efficiently and reliably. These pumps are intricate machines composed of various components that work in harmony to achieve the desired fluid flow. For any centrifugal pump system, the quality and precision of its parts are of utmost importance. In this article, we will delve into the different parts of a centrifugal pump and highlight the significance of choosing a top centrifugal parts manufacturer in Ahmedabad, India, to ensure the reliability and performance of these essential machines.

The Significance of Quality Centrifugal Pump Parts

Centrifugal pumps are used across various industries, including agriculture, manufacturing, water treatment, and more. They are employed for tasks such as moving water, chemicals, oil, and other fluids. In such critical applications, the reliability and efficiency of a centrifugal pump depend largely on the quality of its parts.

Choosing the right centrifugal parts manufacturer is essential for several reasons:

Precision and Durability:

High-quality parts are engineered with precision and manufactured using durable materials at Aashapuri Engineering, Ahmedabad, one of the top Centrifugal Pump Manufacturer in Gujarat. This ensures that they can withstand the rigors of continuous operation and handle a wide range of fluids and conditions.

Optimal Performance:

The performance of a centrifugal pump is directly influenced by the quality of its components. Well-designed and accurately machined parts maximize the pump’s efficiency, resulting in energy savings and improved productivity of the top centrifugal parts manufacturers in India.

Longevity:

Quality parts contribute to the longevity of a centrifugal pump. A pump with reliable components can serve for many years with minimal maintenance, reducing downtime and replacement costs.

Safety:

In industries where the fluids being transported can be hazardous, the safety of the pump and its components is paramount. High-quality parts are less likely to fail or malfunction, reducing the risk of accidents and spills.

Now, let's explore the various essential parts that make up a centrifugal pump.

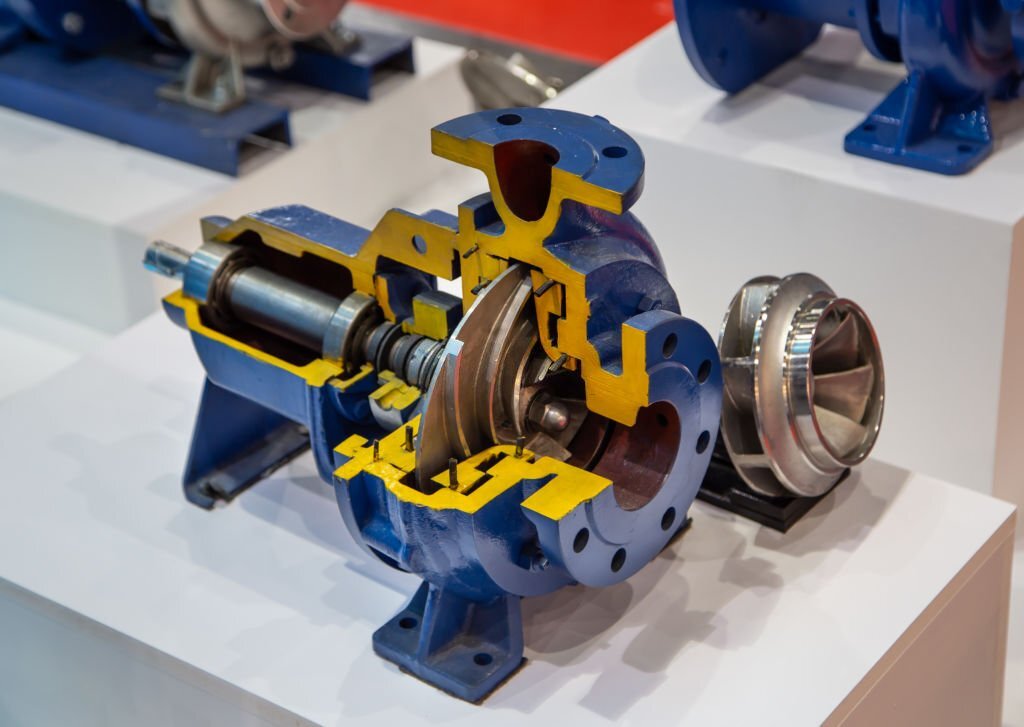

1. Impeller

The impeller is a key component of a centrifugal pump responsible for creating fluid flow. It consists of a series of blades or vanes attached to a central hub. When the impeller rotates, it draws in fluid from the inlet and imparts kinetic energy to it, causing it to move outward in a radial direction. The design of the impeller and the number of blades play a crucial role in determining the pump’s performance.

2. Casing

The casing is the outer shell of the centrifugal pump, surrounding the impeller and other internal components. It is designed to direct the flow of fluid and convert the kinetic energy imparted by the impeller into pressure energy. The casing’s shape and size are critical factors in determining the pump’s efficiency and performance.

3. Shaft

The shaft is responsible for transmitting power from the motor to the impeller. It connects the impeller to the motor and rotates along with the impeller. The quality and strength of the shaft are essential to ensure that it can withstand the stresses and loads placed on it during operation.

4. Bearings

Bearings support the shaft and allow it to rotate smoothly within the pump. High-quality bearings reduce friction and wear, increasing the pump’s efficiency and lifespan. Proper lubrication of the bearings is also crucial to prevent overheating and premature failure.

5. Seal

Seals are used to prevent the leakage of fluid from the pump. They are typically located at various points in the pump, including the shaft seal, which prevents fluid from entering the motor. Choosing quality seals is essential for maintaining the integrity and safety of the pump system.

6. Motor

The motor provides the power necessary to drive the pump’s impeller. Motors can vary in size and type, depending on the application and power requirements of the centrifugal pump. Quality motors are efficient and reliable, contributing to the overall performance of the pump.

7. Suction and Discharge Components

Suction and discharge components, including pipes, fittings, and valves, are essential for the proper operation of the centrifugal pump. These components ensure that fluid is drawn in from the source and discharged to the desired destination.

Choose the Top Centrifugal Parts Manufacturer in Ahmedabad, India.

When it comes to sourcing parts for your centrifugal pump, selecting the top centrifugal parts manufacturer in Ahmedabad, India, is critical. Here are some key considerations to keep in mind when choosing a manufacturer:

1. Experience and Expertise: Look for a manufacturer with a proven track record and extensive experience in producing high-quality centrifugal pump parts like Aashapuri Engineering in Ahmedabad, one of the top manufacturers of centrifugal pump parts in Ahmedabad. Their expertise should encompass a wide range of industries and applications.

2. Quality Control: Ensure that the manufacturer has stringent quality control processes in place. This includes material testing, precision machining, and thorough inspections to guarantee the reliability of their parts, all of which is guaranteed at the top centrifugal parts manufacturer in Gujarat, Aashapuri Engineering in Ahmedabad.

3. Customization Capability: Different pump systems have unique requirements, and a top manufacturer of Centrifugal Pump Parts like Aashapuri Engineering in Gujarat, should be capable of providing customized solutions to meet specific needs.

4. Material Selection: The choice of materials is crucial in determining the durability and performance of pump parts. A reputable manufacturer should use materials that are compatible with the fluids being transported and resistant to corrosion and wear.

5. Timely Delivery: Efficiency in production and timely delivery of parts are essential to minimize downtime and keep operations running smoothly.

6. Customer Support: Consider a manufacturer that offers excellent customer support and is responsive to inquiries, technical assistance, and after-sales service.

Conclusion

A centrifugal pump is only as reliable and efficient as the quality of its components. Choosing the top centrifugal parts manufacturer like Aashapuri Engineering in Ahmedabad, is paramount to ensuring the longevity, performance, and safety of your pump system. High-quality parts, including the impeller, casing, shaft, bearings, seals, motor, and suction/discharge components, all play crucial roles in achieving optimal pump performance.

Investing in top-notch centrifugal pump parts not only improves the efficiency and reliability of your pump system but also contributes to the overall success of your operations. The right manufacturer will offer precision-engineered parts that meet your specific requirements, setting you on the path to uninterrupted fluid transport and increased productivity. When it comes to centrifugal pumps, quality parts are the foundation of success. Therefore, choose the best centrifugal pump parts manufacturer in Ahmedabad, India The Aashapuri Engineering.