Global Demand for Indian Centrifugal Compressor Parts: An Analysis

India has become a big player in the world of manufacturing, especially when it comes to making parts for centrifugal compressors. These parts are crucial in many industries, like oil and gas, petrochemicals, and power generation. This blog will explore why the world needs Indian centrifugal compressor parts, focus on important companies like Aashapuri Engineering Pvt Ltd, and discuss the different types of parts made in India, such as balance weights, bodies, casings, and distance plates. We will keep it simple and easy to understand for everyone, even kids!

What Are Centrifugal Compressors?

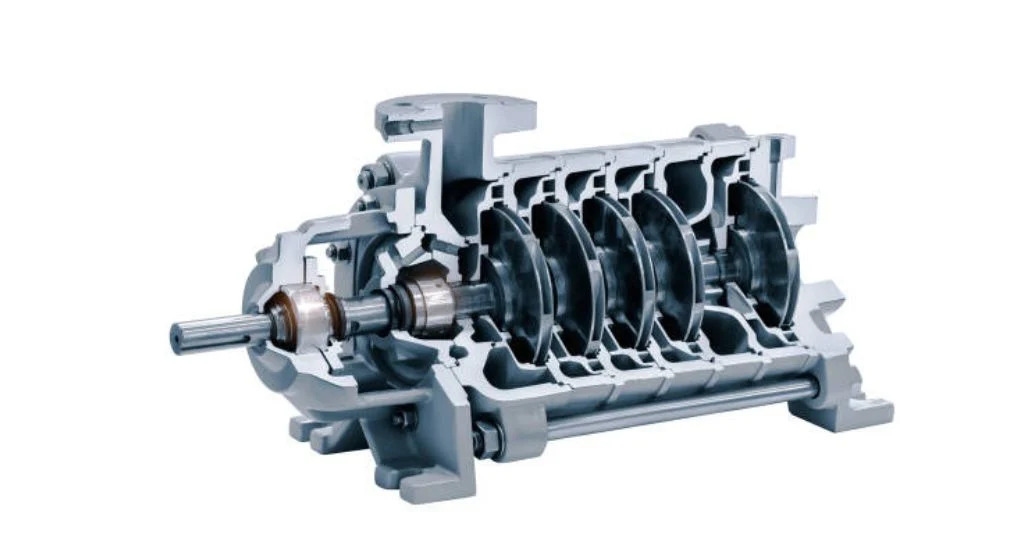

A centrifugal compressor is like a big, powerful fan that squeezes gas to make it more pressurized. Imagine blowing up a balloon. You push air inside to make it bigger and tighter. That’s what a centrifugal compressor does, but with gas. These compressors are used in many places like natural gas processing, refrigeration, and air conditioning. They have many important parts, including the rotor (the spinning part), casing (the outer shell), impellers (the fan blades), and diffuser (which directs the gas).

Why Are Indian Manufacturers Important?

India’s factories have grown a lot, and many companies now make really good machine parts. Aashapuri Engineering Pvt Ltd is one of these companies, known for making top-notch centrifugal compressor parts. Here are a few reasons why people around the world like to buy from Indian manufacturers:

- Affordable Prices: Indian companies can make high-quality parts at lower costs, which saves money for buyers.

- High Quality: These companies follow strict quality rules, ensuring their parts are reliable and durable.

- Skilled Workers: India has many skilled workers who know how to make complicated machine parts with great precision.

Important Centrifugal Compressor Parts Made in India

Indian manufacturers make several key parts for centrifugal compressors. Let’s look at some of them:

1. Centrifugal Balance Weights

Balance weights help keep the rotor steady, reducing vibrations and making the compressor work smoothly. Centrifugal Balance Weight Manufacturers in India make these weights with great care to ensure they fit perfectly and do their job well.

2. Centrifugal Bodies

The body of a centrifugal compressor is like a strong shell that holds everything inside. It needs to be tough to handle high pressures and temperatures. Centrifugal Body Manufacturers in India make durable bodies that can withstand harsh conditions in different industries.

3. Centrifugal Casings

Casings are like the protective cover that surrounds the impeller and diffuser. They guide the gas flow and prevent leaks. Centrifugal Casing Manufacturers in India create strong and efficient casings to ensure the compressor works properly.

4. Centrifugal Distance Plates

Distance plates keep the impeller and casing at the right distance from each other, preventing them from touching and causing damage. Centrifugal Distance Plate Manufacturers in India make these plates with precise measurements to ensure they fit perfectly and function correctly.

Aashapuri Engineering Pvt Ltd: A Key Player

Aashapuri Engineering Pvt Ltd is a leading company in India that makes centrifugal compressor parts. They are known for their high-quality products that meet international standards. The company makes a variety of parts, including balance weights, bodies, casings, and distance plates, and sells them both in India and around the world.

Innovation and Quality

Aashapuri Engineering Pvt Ltd uses modern machines and new technologies to make their parts. This helps them produce very precise and reliable components. Their commitment to quality and innovation makes them a favorite choice for many global customers.

Why is There Global Demand for Indian Parts?

The world needs more and more centrifugal compressor parts from India because of several reasons:

- Industrial Growth: Industries like oil and gas, petrochemicals, and power generation are growing, which means more need for compressors and their parts.

- Better Technology: Indian manufacturers are getting better at making advanced and efficient parts, making them competitive in the global market.

- Diverse Supply Chains: Many companies want to buy from different countries to avoid relying on just one source. India is a reliable option because of its strong manufacturing capabilities.

Challenges and Opportunities for Indian Manufacturers

Even though the demand is high, there are still some challenges and opportunities for Indian manufacturers:

Challenges

- Competition: Indian companies face competition from other countries, especially China.

- Quality Control: Keeping the quality high is essential to maintain trust and compete internationally.

- Supply Chain Issues: Problems like the COVID-19 pandemic showed how supply chains can be disrupted. Manufacturers need plans to handle such risks.

Opportunities

- Export Growth: Indian manufacturers can explore new markets and increase their exports.

- Innovation: Investing in new technologies can help make more advanced and efficient parts.

- Sustainability: More customers want eco-friendly products. Companies that use green manufacturing practices can attract these customers.

Conclusion

The global demand for Indian centrifugal compressor parts shows how much India has grown in the manufacturing sector. Companies like Aashapuri Engineering Pvt Ltd are leading the way by providing high-quality components needed in many industries. As the world changes, Indian manufacturers have a great chance to strengthen their position in the global market by focusing on quality, innovation, and sustainability.

India’s machine component manufacturers have a bright future. With ongoing investment in technology and skilled workers, India can become a world leader in this field. The growing need for centrifugal compressors and their parts gives Indian manufacturers a fantastic opportunity to make a big impact worldwide, supplying essential parts that keep industries running smoothly.

By understanding the importance of these parts and the role of Indian manufacturers, we can appreciate how vital they are to many industries around the world. So next time you think about big machines and how they work, remember the skilled workers in India who make it all possible!