Centrifugal pumps are vital parts that are used in lots of locations, including water treatment, chemical processing, and oil and gas. These pumps are made to transport fluids by the conversion of energy through a piping system. However, just like any other mechanical product, they require periodic inspection and maintenance so that they operate at their optimum level of performance for their extended service life. In this blog, we will discuss how periodic inspection can stretch the service life of parts in the centrifugal pump. We will also introduce Aashapuri Engineering Pvt Ltd, a Centrifugal Pump Parts Manufacturer in India, and Centrifugal Pump Plug Manufacturer in India, as one of the high-quality product-producing companies.

What is a Centrifugal Pump?

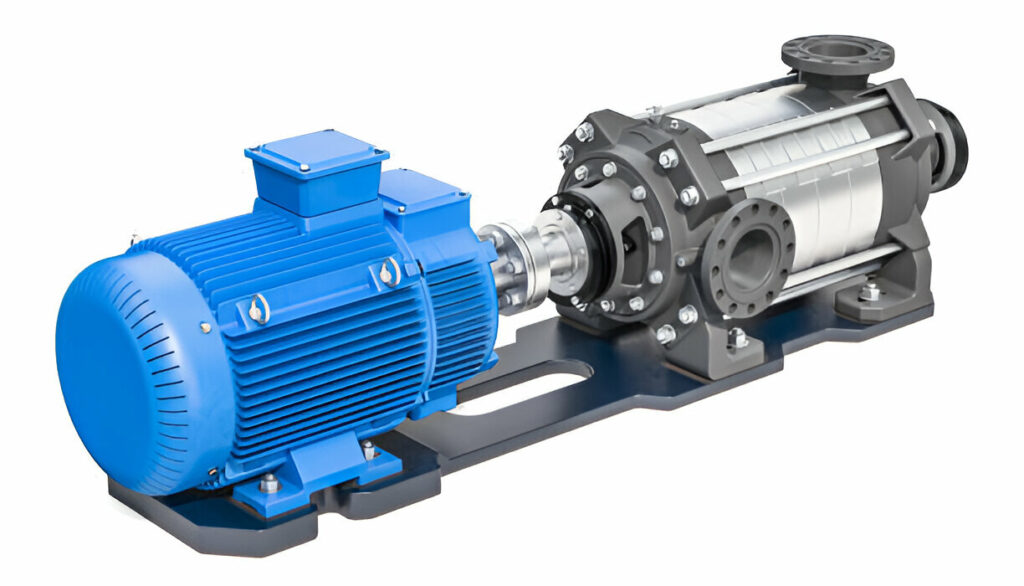

Centrifugal pumps operate on the principle of transformation of rotational energy into fluid energy. Its components include the impeller, casing, shaft, bearings, and seals. The rotating part of the impeller is that part that imparts kinetic energy to the fluid, while the casing, which conducts the flow of the fluid into the discharge, is a static part. Any of the components can play an important role in contributing to or affecting pump efficiency, so if there is wear and tear in any part, it can result in inefficiency or pump failure.

Importance of Periodic Inspection

1. Detection of Effects of Wear Early

The early detection of wear and tear is one of the major benefits of frequent inspection. Impellers and seals are always under stress and can, therefore, wear out in due course. Inspections allow technicians to evaluate the state of these components and replace them just before they fail altogether. This will avoid sudden breakdowns and costly repairs so that the pump keeps working effectively.

2. Maximum Output

The pumps are also able to work at their peak just in case there are regular checks. Cavitation, corrosion, and erosion are factors that can bring imperfections to the pump components. Such imperfections would be recognized through the checks, thus technicians would be able to offer adjustments or repairs. This will enhance the performance of the pump as well as energy efficiency, saving money in the long run.

3. Extend Component Life

In most cases, centrifugal pumps can be a rather expensive investment for any operation, so it is crucial for them to have as long of a life cycle as possible to maximize return on investment. Often, inspections provide information about potential problems before they become major headaches. This way, parts can be repaired and other items replaced at an economic cost, just like in the case where signs of erosion have appeared on an impeller—some damage will probably be done to the casing, as well as other parts—so it is imperative to change out the impeller to avoid expensive repairs later on. Aashapuri Engineering Pvt Ltd is considered one of the major Centrifugal Pump Parts Manufacturers in India. They offer high-quality components that are resistant to wear and tear, thus adding to a longer pump life.

4. Prevention of Contamination

Contamination is one of the most common causes of pump failure. Fluid circulation and carrying debris will cause wear on internal parts and create ineffective and failure-prone assemblies. Frequent inspections can locate sources of contamination and guarantee clear, functioning filters and strainers. Through protection of the integrity of the pump and components, operators can realize increased longevity.

5. Safety Improvement

Regular inspections also form another critical element for the safety of the operation. A cracked pump can lead to leakages or complete failure, thus posing significant safety aspects, not only to the workers but also to the environment. Regimens to inspect pumps ensure that any hazard, in whatever form it might be, can be acted on before it becomes a more serious problem. Safety protection aside, this approach also assists in keeping an aspect that is diligently needed—the compliance of the industry.

Routinely Inspection of Best Practices

To receive adequate benefits from routine inspection, the following best practices must be implemented:

1. Timetable

It is recommended that routine schedule inspection of the pump be placed based on operating conditions and manufacturer’s recommendations. The routine checks include visual checks, performance monitoring, and assessment of key components in detail.

2. Training Personnel

The people responsible for conducting the inspection should be trained on pump operation and its maintenance. Knowledge of the specific demands of the centrifugal pump along with their various parts is something that must be maintained in order to implement effective inspections.

3. Quality Parts

Replace only when necessary. Obtain only good material from good manufacturers. Aashapuri Engineering Pvt Ltd is one of the prominent Centrifugal Pump Plug Manufacturers in India, which assures quality parts that could altogether better the entire performance and life of a centrifugal pump.

4. Records

Maintain records of inspections, repairs, and replacements. This can be used in tracking trends over time and help with the performance analysis of the pump. In addition, this can also be used in planning maintenance in the future and in budgeting.

5. Maintain a Culture of Maintenance

Engage the organization with a culture of maintenance. Probe any weird noise or performance abnormality with the staff immediately. It creates an environment whereby maintenance is found first in achieving the reliability of the pump system.

Conclusion

In conclusion, regular inspection increases the life of centrifugal pump components. Operators can maintain optimal performance, avoid contamination, and be safe once early wear and tear of their pumps are easily detected, thereby ensuring a long time of optimal function. Companies such as Aashapuri Engineering Pvt Ltd, one of the best Centrifugal Pump Parts Manufacturers in India and Centrifugal Pump Plug Manufacturers in India, offer high-quality parts that help centrifugal pumps last longer. Organizations can prevent the losses that their investments incur and also improve their operations by giving priority to regular inspections and using reliable parts. Contact us if you need more information!