A number of key concerns in industrial machinery or equipment revolve around aspects of precision and efficiency. Such a concept includes timing pulleys in mechanical engineering that, although unsung at times, have served to enhance efficiency and performance in several aspects of their industrial applications.

Understanding Timing Pulleys

- What Are Timing Pulleys? Timing pulleys are mechanical devices that transmit power between shafts in exact synchronization. Unlike the standard pulleys, timing pulleys have teeth that interlock with the teeth of a timing belt. The tooth action provides a positive drive method without slippage for better precision in power transmission.

- How Timing Pulleys Work The teeth of the timing belt engage with those of a timing pulley to precisely transmit the movement of the belt onto the pulleys. This is necessary on many grounds; it ensures that everything functions correctly and predictably for a long period of time. These are also widely employed in many fields, starting from automotive engines to industrial machinery, where there is a need to maintain accurate timing and synchronization.

Timing Pulleys: Advantages in an Industrial Setup

- Enhanced Precision Timing Pulleys The main advantages of timing pulleys are the ability to maintain precise timing between shafts. This is very important, especially in settings where there can be no option for precise timing. These are many incidents in conveyor systems, computers, and robotics. Because there can be no slippage, the timing pulley ensures that no section of the machine performs at a low level.

- Improved Efficiency The timing pulleys have significantly improved the efficiency of power transmission. Unlike conventional pulleys that are usually prone to slipping and hence power loss, timing pulleys ensure a direct drive, hence reducing energy wastage. Increased efficiency therefore translates into reduced operations costs and improved productivity generally.

- Reduced Maintenance Timing pulleys reduce the need for constant maintenance. Timing belts and pulleys have been manufactured in a way that they could work together with very minimal abrasion. This, in turn means they require less frequent adjustments than drive systems. Since the frequency of maintenance is lesser, it saves time and increases the life cycle of machinery.

- Noise Reduction Timing pulleys, together with timing belts, ensure relatively quieter operations than conventional belt and pulley drives. The interference of the teeth in engagement reduces vibration and noise, hence guaranteeing a good working environment, combined with reduced risk of noise-related problems in industry.

- Improved Load Carrying Capacity Timing pulleys, thus, are capable of withstanding heavier loads compared to general pulleys. Since the contact area is increased due to the teeth in the timing belt and timing pulley, the spreading out of the load is more even. This is the reason why timing pulleys are ideal in high torque applications and heavy-duty machinery.

Industrial Applications of Timing Pulleys

- Conveyor Systems In conveyor systems, timing pulleys ensure that the belts are always on time, working in perfect synchrony. This view is important for maintaining the consistency of materials and products moving along the conveyor. The application of timing pulleys helps avoid the creation of jams, hence helping in smooth operation that is so vital in maintaining production efficiency.

- CNC Machines The field of Computer Numerical Control machines involves a field of precise movement and synchronization to create proper cutting and machining. Also, in these applications, timing pulleys are important in the accurate control of the movement of the machine, leading to finished products that are quality with reduced material wastage.

- Robotics Timing pulleys can be found in robotic systems to coordinate the movement of different robotic arms and other components. These will result in high precision in timing and minimal slippage, hence facilitating the execution of complicated tasks with high accuracy, which enhances the performance of robotic systems generally.

- Automotive Industry The timing pulley is also vitally used in automotive engines to allow for the synchronization of the crankshaft and camshaft rotational motion. In that, opening and closing times of the engine valves must be so because proper synchronization ensures better performance and economy of the engine.

- Packaging Machinery In packaging machinery, the timing pulleys play a great role in maintaining the exact motion of belts and rollers. For accurate placement of products, labeling, and packaging of the product, precision plays a key role in ensuring error-free packaging with great efficiency.

Selection of the Right Timing Pulley

- Selection of Material Material variation is the second most important factor one must consider when choosing a timing pulley. Materials used include aluminum, steel, and plastic. Chosen material shall depend on load capacity, environmental condition, and cost.

- Size and Pitch The size and pitch of the timing pulley must be in line with that of the timing belt that is going to be installed. For effectiveness and efficiency, accuracy of alignment between the pulley and the belt is important.

- Tooth Profile Various timing pulleys come with different tooth profiles, such as trapezoidal or curvilinear. The type of tooth profile will depend upon the needs of the application and the kind of timing belt manufactured.

- Quality of Manufacturer The quality may not be the same, according to the company producing them. Since there are genuine Timing Pulley Manufacturers in India, you will obtain quality parts, which respond to the needs of the sector in giving the best performance.

The Most Prevalent Manufacturers in India

- Timing Pulley Manufacturers in India Manufacturers of timing pulleys in India range from highly valued in various parts of the world for assurance in high-quality components that fit various industrial applications. The local manufacturers generally make use of international standards while producing timing pulleys, availing state-of-the-art technologies and materials to that effect. Companies like Aashapuri Engineering Pvt Ltd have their reputation in designing and manufacturing timing pulleys that exactly fit the industrial needs of their customers.

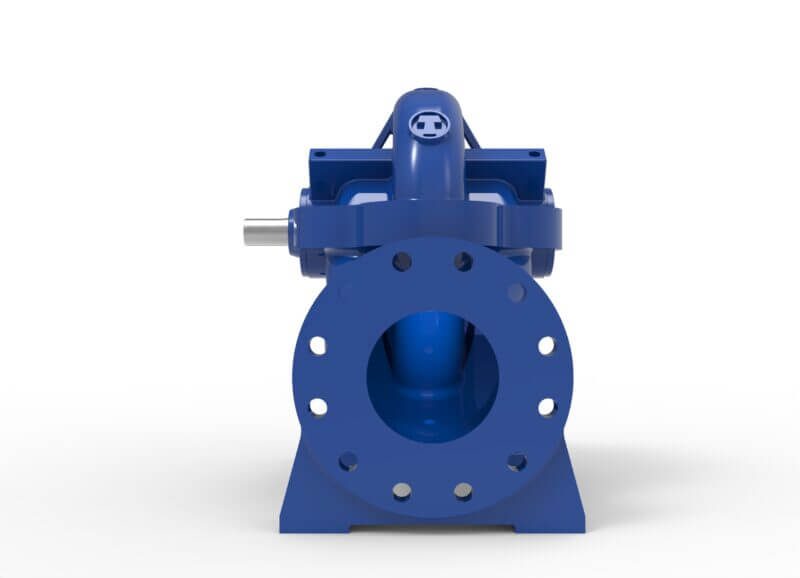

- Centrifugal Pump Plug Manufacturer in India Besides timing pulleys, centrifugal pump plugs are also highly essential in many industrial fields. Aashapuri Engineering Pvt Ltd is one of the topmost Centrifugal Pump Plug Manufacturers in India manufacturing high-quality plugs to maintain complete efficiency of centrifugal pumps. Centrifugal pump plugs ensure no leakage and retain the performance of the pump systems.

Conclusion

In summary, timing pulleys are pivotal in improving industrial efficiency and performance. They are essential for ensuring precise synchronization, enhancing operational efficiency, and minimizing maintenance requirements, especially in heavy-duty applications. As industries continue to advance, the need for precision and reliability in components like timing pulleys becomes even more critical, making them an integral part of modern machinery.

Choosing the right timing pulleys is crucial for meeting specific operational demands and maintaining high-quality standards. Aashapuri Engineering Pvt Ltd, a leading manufacturer in India, has established itself as a trusted name due to its expertise, reliability, and commitment to innovation in producing timing pulleys and related components.

In essence, timing pulleys are key components in industrial machinery, helping to optimize performance and reduce maintenance costs. By understanding their importance and selecting a reputable manufacturer, industries can fully capitalize on the benefits timing pulleys offer.

For further details or to discuss your specific requirements, don’t hesitate to reach out to us. We’re here to provide expert guidance and solutions tailored to your needs.