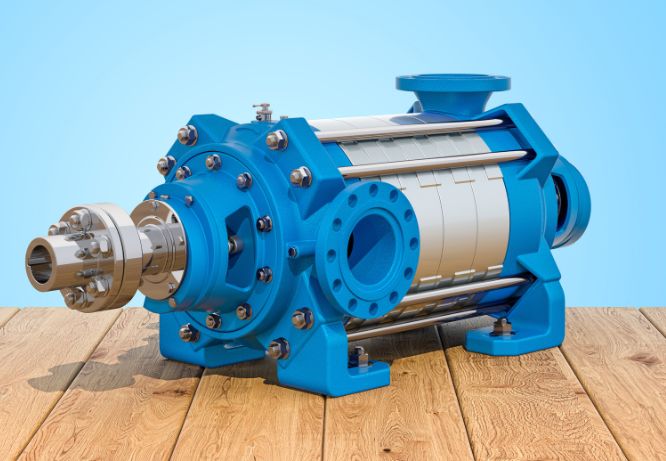

The balancing of a centrifugal machine is significant to its optimum reliability and life. It does not matter whether you are using a centrifugal pump, a fan, or any other rotating equipment; balancing is used to reduce the occurrence of vibrations, wear out, and improve the general efficiency of the machine. In this blog read ahead on how a balancing centrifugal machine works and why the process is so critical; also, the blog talks about what a manufacturer like Aashapuri Engineering Pvt Ltd, one of the leading Centrifugal Balance Weight Manufacturer in India does.

Understanding Centrifugal Balance

Like pumps, fans, and turbines, centrifugal machines work by moving at high rotary speeds. During this rotation, centrifugal forces will be created, thereby having the potential to cause imbalances within the system. Imbalances that can be caused include manufacturing errors, non-uniform wear, and worsened assembly conditions. Balancing in this context refers to equalizing the weight degrees of the rotating pieces to allow them to work stably without creating extreme vibrations.

Importance of Balancing

- Vibration Reduction: Unbalanced centrifugal machines leave vibration tendencies on the machinery that could develop into noise and possibly damage the machine and surrounding paraphernalia. Excessive vibrations cause misalignment, increased wear, and even failure of bearings and shafts, leading to premature failure. Proper balancing reduces it to a minimum level of vibration, enabling smooth and quiet operation.

- Prolongation of Equipment Life: This puts additional stress on the rotating parts of a machine, which increases the wear and tear on those parts. Over time, this can result in reduced life of important components, an increased cost of maintenance, etc. Balance reduces the load put on the equipment, which may greatly extend its useful life.

- Better Performance: An unbalanced centrifuge will not be able to perform to its designed efficiency. All the imbalances result in a lot of inefficiency and sometimes even reduced performance—for example, reduced flow rates in pumps or lower efficiency in fans. Proper balancing will enable it to perform at its optimum and ensure that it meets all the desired standards of performance. Machines working with imbalances are more likely to use some extra amount of energy against those additional vibrations and stresses. These lead to increased energy consumption and add to the costs of operations. An imbalanced machine is not operating in its ideal state; hence, it increases the consumption of energy.

- Safety: An unbalanced centrifugal machine can be associated with various safety issues. Excessively high vibrations can create many hazardous situations, leading to breakage of parts or accidents. Most of these risks get eliminated, and the general state of safety for the equipment and humans is enhanced by doing an adequate balancing.

Balancing a Centrifugal Machine

- Examine and Prepare: Carefully inspect the machine for any visible evidence of damage or wear before initiating the balancing process. Ensure that all components are installed and secured properly, and the machine is cleared of dirt and other waste or debris that could disrupt the balancing process. Use vibration analysis tools for determining the magnitude and location of imbalance. These tools are used to measure the amplitude and frequency of vibrations, which help in the identification of the source of imbalance. Such tools usually include vibration sensors, accelerometers, and data acquisition systems.

- Balance Weights: Use the data from the vibration analysis to put proper weights on the machine to balance out an imbalance. That is to mean, some weight has to be added, removed or in some cases, modification of some weights. You may, at times, want to pick the use of specialist equipment like the Centrifugal Weight for Balancing Manufacturer in India that will give you very precise weights when you want the weight for purposes of balancing.

- Re-Test and Fine Tune: Test-run the machine again after making the adjustment to check that imbalance has been eliminated. Monitor the vibrations and further adjust if need be. Fine-tuning may be required for optimal balance.

- Document and Maintain: Document the balancing process, including the adjustments made and the final vibration readings. Regularly monitor and maintain the machine to ensure that the balance is maintained over time. Periodic rebalancing may be necessary as the machine ages or undergoes changes in operation.

The Role of Aashapuri Engineering Pvt Ltd

The process of balancing requires good components and precisely accurate weights. Aashapuri Engineering Pvt Ltd is among the top companies for the manufacturing of Centrifugal Balance Weight in India and Centrifugal Weight for Balancing in India. They have worldwide expertise in manufacturing balancing weights and components with higher precision for the balancing of machines, which can run precisely and do justice to the performance and longevity.

Aashapuri Engineering Pvt Ltd offers a variety of centrifugal balance weights that are designed to fulfill centrifugal machine requirements. They stand for ideal accuracy, durability, and reliability, which makes them the leading choice for many industries in need of high-quality balancing solutions.

Conclusion

The centrifuge balancing is a very important function towards efficiency, life, and safe and reliable operation of the centrifugal machine. If done correctly and great components are used from known manufacturers, such as Aashapuri Engineering Pvt Ltd, of course, it will guarantee optimum performance with minimal equipment failure.

The best industrial practices for any set-up using a centrifugal-based machine include regular balancing and maintenance. Investing in these practices enhances not only the performance and raised safety level of the equipment, but also helps contribute to overall operational efficiency and cost savings.

For a detailed inquiry regarding centrifugal balance weights and the balancing of the same or similar lines of products, write to Aashapuri Engineering Pvt Ltd.