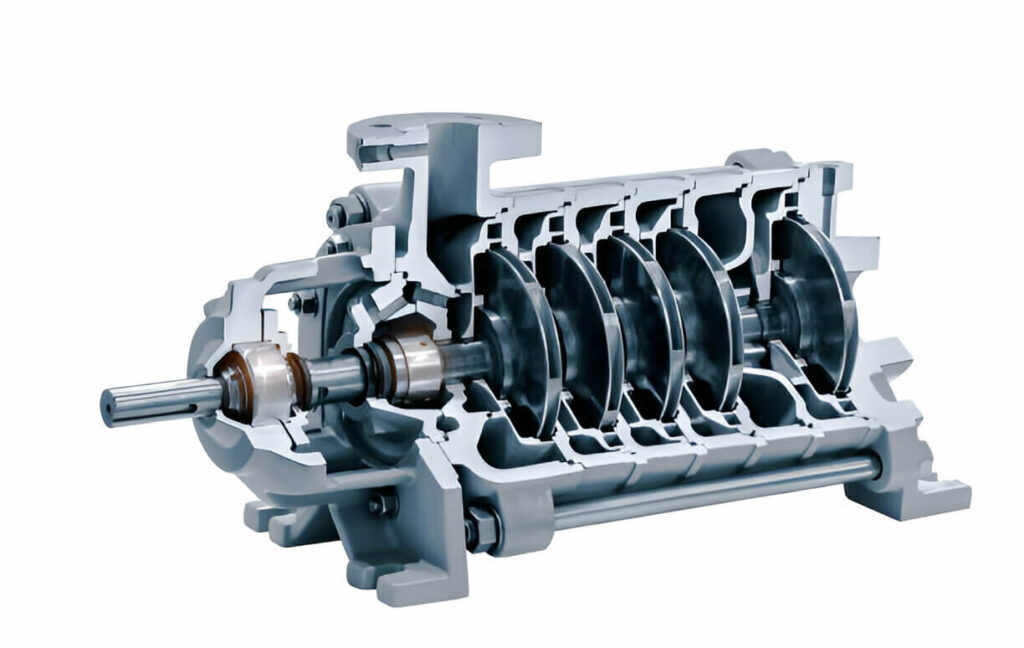

Centrifugal compressors are integral to several industries, including power generation, petrochemicals, oil & gas, refrigeration, and HVAC systems. These compressors are crucial because they generate the necessary pressure to ensure the smooth operation of processes, providing a steady flow within systems. As industries rely heavily on centrifugal compressors for efficiency, the quality of the parts used in these machines is critical for ensuring their durability, performance, and safety.

In recent years, there has been a surge in demand for high-quality centrifugal compressor parts in India, leading to the growth of numerous manufacturers. It is essential to carefully assess the quality of centrifugal compressor parts manufacturer in India to identify those who can provide reliable, long-lasting components. In this blog, we will walk you through key factors to consider when evaluating centrifugal compressor parts manufacturers in India, using Aashapuri Engineering Pvt Ltd as an example of a top-tier manufacturer.

1. Assessing the Manufacturer’s Reputation

A manufacturer’s reputation is one of the first indicators of product quality. A good centrifugal compressor parts manufacturer should have a proven track record of delivering high-quality components and maintaining long-term relationships with clients.

For instance, Aashapuri Engineering Pvt Ltd has built a stellar reputation over several decades by prioritizing quality, innovation, and customer satisfaction. This commitment has earned them loyal clients in India and internationally.

To evaluate a manufacturer’s reputation, consider the following:

- Client Reviews: Look for customer reviews or testimonials to gauge the manufacturer’s reliability and product quality.

- References and Case Studies: A reliable manufacturer like Aashapuri can provide case studies or references from clients, especially those in similar industries to yours.

2. Certifications and Quality Standards

Manufacturers who adhere to international standards and possess relevant certifications are more likely to provide high-quality products. Certifications are a sign that the manufacturer’s processes and products meet stringent global quality and safety standards.

Key certifications to look for include:

- ISO 9001: This certification indicates that the manufacturer has established effective management systems for its processes.

- ISO 14001 or OHSAS 18001: These certifications are related to environmental management or occupational health and safety standards.

- Industry-Specific Certifications: Depending on your industry, you may also look for certifications like API (American Petroleum Institute) or ASME (American Society of Mechanical Engineers).

Aashapuri Engineering Pvt Ltd holds ISO 9001 certification, ensuring their commitment to quality control and customer satisfaction, aligning with the rigorous demands of industries requiring centrifugal compressor parts.

3. Robust Quality Control Processes

Effective quality control is vital in ensuring the reliability and longevity of centrifugal compressor parts. A reputable manufacturer should have stringent processes in place to guarantee that each part is flawless before it leaves the factory.

When evaluating quality control practices, ask about:

- Inspection and Testing Procedures: A trustworthy manufacturer will conduct detailed inspections, including size checks, material testing, and performance tests, on raw materials, in-process components, and finished products.

- Material Quality: The choice of raw materials used for compressor parts is crucial. A manufacturer should use high-quality alloys and metals that can withstand extreme pressure and temperature conditions.

Aashapuri Engineering Pvt Ltd is known for its meticulous quality control, utilizing non-destructive testing methods to ensure each part meets the highest standards of performance and reliability.

4. Experience and Technical Expertise

The experience and technical skill of a manufacturer play a critical role in the production of high-quality centrifugal compressor parts. A manufacturer with years of experience and a team of qualified engineers will have refined their manufacturing processes and developed a deep understanding of centrifugal compressors.

Factors to consider when assessing experience:

- Years in Business: Companies like Aashapuri Engineering Pvt Ltd, which have been in the business for decades, bring years of expertise in optimizing centrifugal compressor performance.

- Engineering Capabilities: A manufacturer should have a team of skilled engineers capable of product development, customization, and providing tailored solutions.

Aashapuri Engineering Pvt Ltd’s in-house engineering team ensures that each component is designed and manufactured with precision, ensuring compatibility and optimal performance in the most demanding applications.

5. Product Range and Customization

Centrifugal compressors are used across various industries, and different applications often require customized parts. A manufacturer who offers customization can cater to specific compressor models or operating conditions.

Consider the following when evaluating product range and customization:

- Product Variety: A good manufacturer should offer a broad range of centrifugal compressor parts, including impellers, shafts, rotors, bearings, seals, and more. This range ensures flexibility in meeting the diverse needs of different industries.

- Customization Options: A manufacturer who provides tailored solutions, whether it’s a small modification or a completely redesigned component, can meet the unique specifications of your application.

Aashapuri Engineering Pvt Ltd is known for offering highly customized centrifugal compressor parts that meet specific customer requirements, ensuring optimal fit and performance for each application.

6. Timely Delivery and After-Sales Support

In industries that rely on centrifugal compressors, timely delivery and robust after-sales support are essential to avoid disruptions in operations. A good manufacturer should provide clear delivery timelines and contingency plans for any potential delays. After-sales support ensures that any issues with parts are resolved promptly and that the compressors continue to perform optimally.

When evaluating a manufacturer’s delivery and support, consider:

- On-Time Delivery: A reliable manufacturer should consistently meet deadlines, even for large or urgent orders.

- Warranty and Support: Ensure the manufacturer offers after-sales warranties and has a reliable support system in place to address any issues.

Aashapuri Engineering Pvt Ltd excels in timely delivery and offers comprehensive after-sales support, helping clients maintain their compressors and avoid costly downtime.

7. Price and Value for Money

While quality is the most important factor, price is also a critical consideration. A good manufacturer should offer competitive pricing without compromising on quality. The price should reflect the value of the components, ensuring long-term durability and performance.

When evaluating price, consider:

- Comparative Pricing: Compare the prices of different manufacturers, keeping in mind the quality of materials, manufacturing processes, and certifications.

- Value for Money: Look for manufacturers like Aashapuri Engineering Pvt Ltd, who offer a good balance of cost and quality, ensuring long-term value through durable and reliable parts.

To choose the best centrifugal compressor parts manufacturer in India, it is essential to evaluate factors such as reputation, certifications, experience, product range, and pricing. Aashapuri Engineering Pvt Ltd stands out for its high-quality parts, customization options, expertise, and exceptional customer support, making them a top choice for industries in need of reliable centrifugal compressor components.

Conclusion

In conclusion, choosing the right centrifugal compressor parts manufacturer is critical for ensuring the efficiency, reliability, and longevity of compressors used across various industries. By evaluating key factors such as reputation, certifications, quality control, experience, customization options, timely delivery, and price, businesses can make informed decisions when selecting a manufacturer. Aashapuri Engineering Pvt Ltd exemplifies excellence in all these areas, offering high-quality, customizable parts with a commitment to customer satisfaction and continuous support. With their expertise, innovation, and reliable service, Aashapuri Engineering is a trusted partner for industries looking for a top-notch centrifugal compressor parts manufacturer in India that meets both performance and budget requirements.