Maintenance Tips for Prolonging the Life of Centrifugal Pump Parts

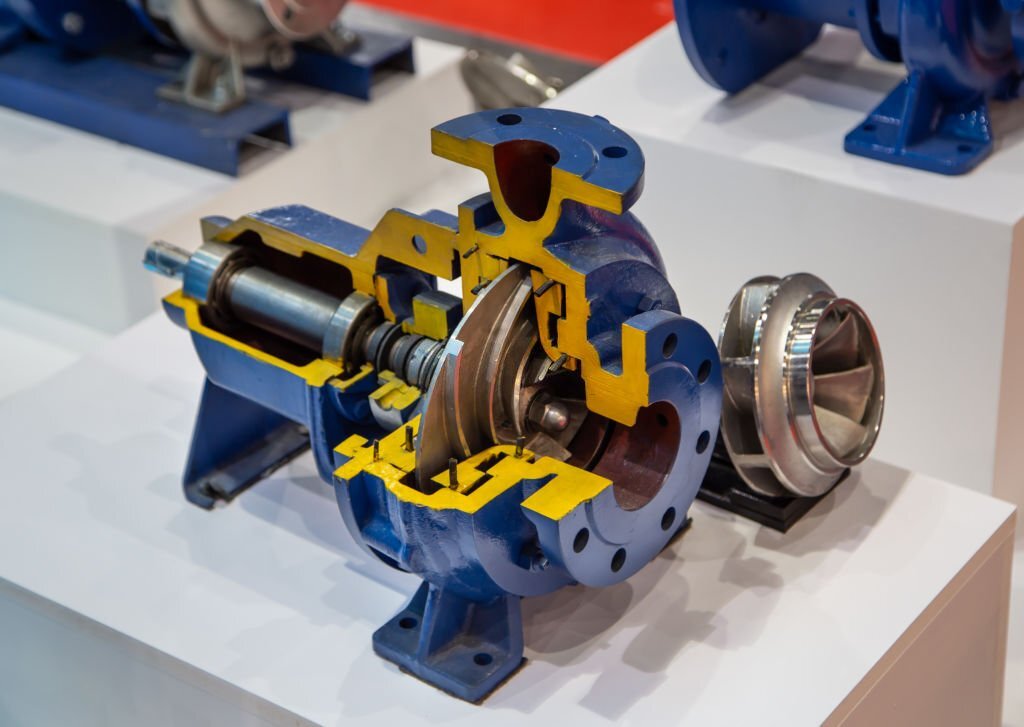

In the realm of fluid handling systems, Centrifugal Pump Parts play a pivotal role in ensuring efficient and reliable operations. Regular maintenance is essential to maximize their lifespan and optimize performance. As a trusted Centrifugal Pump Parts Manufacturer in India, Aashapuri Engineering is committed to providing valuable insights on maintaining these crucial components. Let’s delve into some practical maintenance tips.

Regular Inspection and Cleaning:

One of the fundamental aspects of prolonging the life of Centrifugal Pump Parts is regular inspection and cleaning. Aashapuri Engineering recommends scheduling routine inspections to identify potential issues such as wear, corrosion, or blockages. Cleanliness is paramount to prevent debris accumulation, which can impede the pump’s efficiency.

Lubrication and Bearing Checks:

Proper lubrication is vital for the smooth functioning of pump parts. Aashapuri Engineering suggests adhering to the manufacturer’s guidelines for lubrication intervals and using high-quality lubricants. Additionally, regular checks of bearings are crucial. Replace worn-out bearings promptly to prevent further damage and ensure optimal performance.

Seal Maintenance:

Centrifugal pumps often rely on seals to prevent leakage. Regularly inspect and replace seals as needed to avoid fluid leakage and contamination. Aashapuri Engineering emphasizes the importance of selecting the right type of seal for specific applications, considering factors such as fluid compatibility and operating conditions.

Balancing and Alignment:

Proper balancing and alignment contribute significantly to the longevity of Centrifugal Pump Parts. Aashapuri Engineering recommends performing regular checks to ensure that impellers, shafts, and other rotating components are properly aligned. Imbalances can lead to increased vibration and premature wear, impacting the overall performance of the pump.

Conclusion:

In conclusion, the longevity of Centrifugal Pump Parts is closely tied to proactive and regular maintenance. Aashapuri Engineering, a leading Centrifugal Pump Parts Manufacturer in India, encourages users to implement these maintenance tips to optimize the performance and extend the lifespan of their pump components. By following these guidelines, industries in Gujarat and across India can ensure the reliability and efficiency of their fluid handling systems.

For more information about Centrifugal Pump Parts and other products, visit Aashapuri Engineering.