A timing pulley is an essential component in various mechanical systems, primarily used to transfer rotary motion and synchronize the timing of components in machinery. It is crucial for maintaining the precise movement of belts and ensuring smooth operations in industrial applications. As a prominent timing pulley manufacturer in India, Aashapuri Engineering offers high-quality products that guarantee performance, durability, and efficiency for diverse industries. Whether you’re in automotive, manufacturing, or power generation, selecting the right timing pulley is vital to keeping your machinery running without interruption.

By choosing a trusted timing pulley manufacturer in India, you can ensure that your equipment operates at peak performance, reducing maintenance costs and minimizing downtime. Let’s explore why it’s essential to rely on the expertise of experienced manufacturers for your timing pulley needs.

What is a timing pulley?

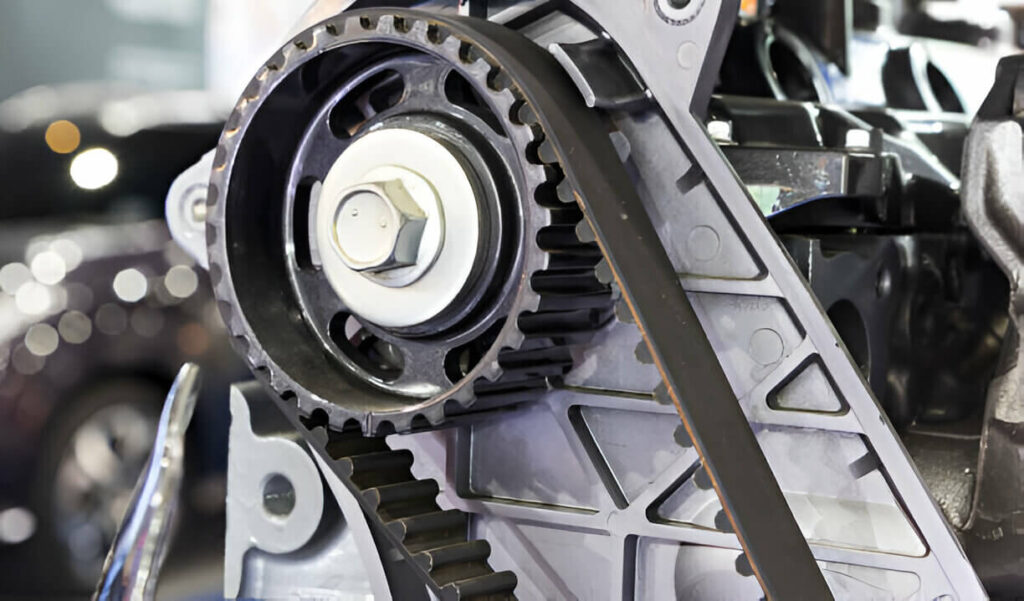

A timing pulley is a crucial component in many mechanical systems, particularly in machines that use belt and pulley systems for power transmission. Timing pulleys are specifically designed with teeth or grooves that mesh with the teeth of timing belts, ensuring synchronization between moving parts. Unlike standard pulleys, timing pulleys allow for precise and controlled movement, which is vital in systems that require synchronization, such as engines, conveyor systems, and pumps.

These pulleys are widely used in various industries because they offer several advantages, including:

- Precision: Timing pulleys help ensure that rotational movement occurs at precise intervals, which is necessary for machinery where timing is critical.

- High Efficiency: They transmit power efficiently by reducing slip between the belt and pulley, minimizing energy losses.

- Durability: Made from durable materials, timing pulleys are designed to withstand significant mechanical stress, contributing to the longevity of the machinery.

Due to these advantages, timing pulleys are an integral part of many industrial applications.

The Importance of Timing Pulley Manufacturer in India

When it comes to ensuring the reliable and efficient operation of your machinery, selecting the right timing pulley manufacturer in India is crucial. A good manufacturer will produce high-quality timing pulleys that meet your exact specifications, ensuring optimal performance. The key to longevity, reduced maintenance costs, and smoother operations lies in using precisely engineered pulleys that fit perfectly within your machinery.

At Aashapuri Engineering, we understand the importance of delivering timing pulleys that not only meet the highest standards of quality but also exceed your expectations. Choosing a reputable manufacturer ensures that you are investing in products that are durable, reliable, and able to withstand the harsh conditions often faced in industrial settings.

Some reasons why selecting a trusted timing pulley manufacturer is vital:

- Expertise and Experience: A manufacturer with years of experience will have the knowledge to deliver products that meet industry standards and function optimally.

- Customization: A trusted manufacturer can customize the pulleys based on your unique requirements, ensuring perfect fit and function.

- Quality Assurance: Reputable manufacturers provide quality assurance and use high-quality materials for all their products.

Applications of Timing Pulleys in Various Industries

Timing pulleys are used across a wide range of industries due to their versatility and reliability. They play a critical role in ensuring that mechanical systems operate efficiently and with precision. Let’s explore the various applications where timing pulleys are integral:

👉Automotive Industry:

In the automotive industry, timing pulleys are essential for ensuring the synchronization of components in engines. Timing pulleys help in controlling the movement of timing belts, which are responsible for syncing the camshaft and crankshaft. This synchronization is crucial for optimal engine performance, power generation, and fuel efficiency.

👉Manufacturing and Automation:

Timing pulleys are widely used in automated machinery to ensure precise and efficient movements. In conveyor systems, packaging machines, and other automated machinery, these pulleys help to control the speed and synchronization of moving parts. Their precision helps maintain consistent production rates and reduces mechanical errors.

👉Power Generation:

In power plants and other energy-generating systems, timing pulleys are crucial for managing the synchronization of turbine rotors, compressors, and other components that require precise timing for effective power generation.

👉Agricultural Machinery:

Farming and agricultural machinery rely on timing pulleys to ensure the efficient movement of parts in equipment like harvesters, tractors, and irrigation systems. Their accuracy is key to ensuring the reliability of these machines in critical environments.

👉Medical Equipment:

Precision is essential in medical equipment, and timing pulleys are used in devices that require controlled movements, such as diagnostic machines, prosthetic equipment, and surgical robots. The accuracy of these pulleys ensures that medical devices perform as intended without failure.

Key Factors to Consider When Choosing a Timing Pulley Manufacturer in India

Choosing the right timing pulley manufacturer in India involves considering several factors to ensure you get the best product for your needs. These include:

✅Material Quality:

The material used for manufacturing timing pulleys plays a significant role in their durability, strength, and ability to withstand harsh conditions. Materials like aluminum, steel, and engineered plastics are commonly used for manufacturing timing pulleys, depending on the application.

✅Precision Engineering:

Timing pulleys require precise engineering to ensure they mesh correctly with timing belts. Look for manufacturers that use advanced manufacturing techniques and high-precision equipment to ensure the accuracy of each pulley produced.

✅Customization Options:

Depending on the specific requirements of your machinery, you may need custom-sized pulleys or pulleys with specific features, such as special tooth profiles or finishes. A good manufacturer should be able to provide customization options to meet these needs.

✅Testing and Quality Control:

Quality control is a critical step in the manufacturing process of timing pulleys. The manufacturer should perform rigorous testing to ensure that each pulley meets industry standards and performs efficiently in real-world conditions. Look for manufacturers who conduct extensive testing, including load testing, wear testing, and durability testing.

✅Reputation and Experience:

A manufacturer and supplier with years of experience and a solid reputation in the industry is likely to provide products that meet or exceed industry standards. Customer reviews, case studies, and testimonials can give you a better understanding of the manufacturer’s capabilities and reliability.

Benefits of High-Quality Timing Pulleys

Investing in high-quality timing pulleys offers several key benefits that can directly impact the efficiency and reliability of your equipment:

1. Enhanced Performance:

High-quality pulleys reduce slip and friction, ensuring that the machinery operates smoothly and efficiently. This leads to better energy utilization and improved performance in mechanical systems.

2. Reduced maintenance costs:

Well-designed and durable timing pulleys are less prone to wear and tear. This means fewer replacements and repairs, helping to reduce long-term maintenance costs. A reliable pulley can last for many years without the need for frequent servicing.

3. Increased Equipment Lifespan:

The durability of high-quality timing pulleys ensures that they contribute to the overall longevity of your equipment. By preventing damage to other critical parts of the machinery, these pulleys help extend the life of the entire system.

4. Minimized Downtime:

With fewer frequent failures and lower maintenance requirements, high-quality pulleys reduce the amount of downtime experienced by your machinery. This allows for consistent and uninterrupted operations, which is crucial for maintaining productivity.

Why Durability Matters for Timing Pulleys

Many applications subject timing pulleys to significant mechanical stress and high rotational speeds, making their durability crucial. If a timing pulley is not durable enough, it can cause wear on the timing belts, misalignment of machinery, and even complete mechanical failure. These issues can lead to costly downtime and repairs.

To ensure long-term reliability, manufacturers must use strong materials that can withstand the forces applied during operation. For example, materials such as steel or aluminum alloy are commonly used due to their strength, wear resistance, and ability to maintain performance under high loads.

A well-built timing pulley should be able to function in harsh operating environments without failing prematurely, thus saving you from frequent replacements and minimizing disruptions to your operations.

Future Trends in the Timing Pulley Industry

As industries continue to evolve, the demand for more efficient and reliable components increases. Here are some of the emerging trends in the timing pulley industry:

- Increased Use of Advanced Materials:

Advancements in material science have led to the development of stronger, lighter, and more corrosion-resistant materials that are ideal for timing pulleys. Composite materials, for example, offer excellent durability while being lighter than traditional metals.

- Automation and Smart Manufacturing:

The rise of automation in manufacturing processes has made it possible to produce more precise and complex timing pulleys. With the integration of Internet of Things technology, manufacturers can now monitor the performance of pulleys in real-time, providing valuable insights into their performance and allowing for predictive maintenance.

- Eco-Friendly Materials:

With sustainability becoming a key concern for industries worldwide, there is a growing trend toward using eco-friendly materials in manufacturing timing pulleys. Biodegradable plastics and recyclable metals are being explored to reduce the environmental impact of industrial production.

Final Thoughts

In conclusion, choosing the right timing pulley manufacturer in India is crucial to the long-term success of your machinery and operations. Quality, precision, and durability are key factors to consider when selecting timing pulleys for your applications. Aashapuri Engineering is dedicated to providing high-performance timing pulleys that meet the unique requirements of your business. Reach out to us now to discover how our knowledgeable team can enhance your machinery performance with our superior timing pulleys.