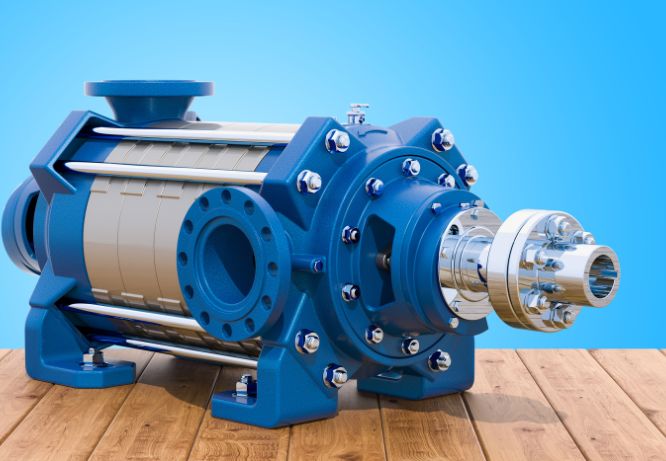

Centrifugal pumps are vital components in various industries, from water treatment and chemical processing to oil and gas. These pumps rely on a rotating impeller to move fluids, and their efficient operation is crucial for maintaining the smooth functioning of industrial processes. However, one common issue that can disrupt their performance is leakage. Understanding and addressing centrifugal pump leakage is essential for ensuring the longevity and reliability of these pumps.

Understanding Centrifugal Pump Leakage

Centrifugal pump leakage can occur due to various reasons, including worn-out seals, damaged bearings, or improper assembly. Leakage not only affects the efficiency of the pump but can also lead to operational hazards, environmental concerns, and increased maintenance costs. Identifying the root cause of leakage is the first step in addressing the problem effectively.

Common Causes of Centrifugal Pump Leakage

- Seal Failure: Seals are designed to prevent fluid from escaping the pump casing. Over time, seals can wear out due to pressure, temperature, and chemical exposure, leading to leakage.

- Worn Bearings: Bearings support the rotating shaft of the pump. If bearings become worn or damaged, they can cause misalignment, leading to leakage around the shaft.

- Impeller Damage: The impeller is a crucial component that helps move the fluid through the pump. If the impeller is damaged or improperly installed, it can cause leakage.

- Casing Corrosion: The pump casing can corrode over time due to exposure to harsh chemicals or abrasive materials, leading to leakage.

- Improper Assembly: If the pump components are not assembled correctly, it can result in leakage. This can happen due to incorrect installation of gaskets, seals, or other parts.

Solutions for Centrifugal Pump Leakage

- Regular Maintenance and Inspection: Regular maintenance is crucial for identifying potential issues before they lead to leakage. Routine inspections can help detect worn seals, damaged bearings, and other components that may need replacement.

- Seal Replacement: If seal failure is identified as the cause of leakage, replacing the seals is a primary solution. Using high-quality seals that are compatible with the pump’s operating conditions can prevent future leakage.

- Bearing Replacement: Worn or damaged bearings should be replaced promptly to avoid further damage to the pump. Regular checks and timely replacement of bearings can prevent misalignment and leakage.

- Impeller Repair or Replacement: If the impeller is damaged, it should be repaired or replaced. Ensuring that the impeller is properly installed and aligned can prevent leakage and maintain pump efficiency.

- Casing Inspection and Repair: Corroded or damaged casings should be inspected and repaired. In some cases, it may be necessary to replace the casing if the damage is extensive.

- Proper Assembly: Ensuring that all pump components are assembled correctly is crucial for preventing leakage. This includes proper installation of gaskets, seals, and other parts.

- Using High-Quality Parts: The use of high-quality centrifugal pump parts can significantly reduce the likelihood of leakage. Working with reputable centrifugal pump parts manufacturers ensures that you receive reliable and durable components.

Role of Centrifugal Pump Parts Manufacturers

Centrifugal pump parts manufacturers play a vital role in providing high-quality components that help prevent and address leakage issues. Aashapuri Engineering Pvt Ltd, a leading Centrifugal Pump Parts Manufacturer in India, is known for its commitment to quality and innovation. The company specializes in producing a wide range of pump parts, including seals, bearings, impellers, and casings, designed to meet the highest standards of performance and durability.

Why Choose Aashapuri Engineering Pvt Ltd?

- Quality Assurance: Aashapuri Engineering Pvt Ltd ensures that all its products meet stringent quality standards. Their components are designed to withstand the harsh conditions of industrial applications, reducing the risk of leakage.

- Expertise and Experience: With years of experience in the industry, Aashapuri Engineering Pvt Ltd has the expertise to provide reliable and effective solutions for centrifugal pump issues.

- Custom Solutions: The company offers customized solutions tailored to the specific needs of its clients. Whether you need standard parts or specialized components, Aashapuri Engineering Pvt Ltd can provide the right solutions.

- Timely Delivery: Efficient service and timely delivery of components are crucial for minimizing downtime and preventing leakage-related issues. Aashapuri Engineering Pvt Ltd is known for its prompt and reliable service.

Conclusion

Centrifugal pump leakage is a common issue that can impact the efficiency and reliability of industrial processes. Understanding the causes of leakage and implementing effective solutions is crucial for maintaining optimal pump performance. Regular maintenance, timely replacement of worn parts, and the use of high-quality components are essential for preventing and addressing leakage issues.

Partnering with a reputable centrifugal pump parts manufacturer like Aashapuri Engineering Pvt Ltd can provide access to high-quality components and expert solutions. By addressing centrifugal pump leakage proactively, you can ensure the smooth operation of your pumps and avoid costly downtime.

If you are experiencing issues with centrifugal pump leakage or need high-quality pump parts, consider reaching out to Aashapuri Engineering Pvt Ltd. Their expertise and commitment to quality can help you find the right solutions for your pump maintenance and repair needs.