The Role of Centrifugal Compressor Parts in Key Industries

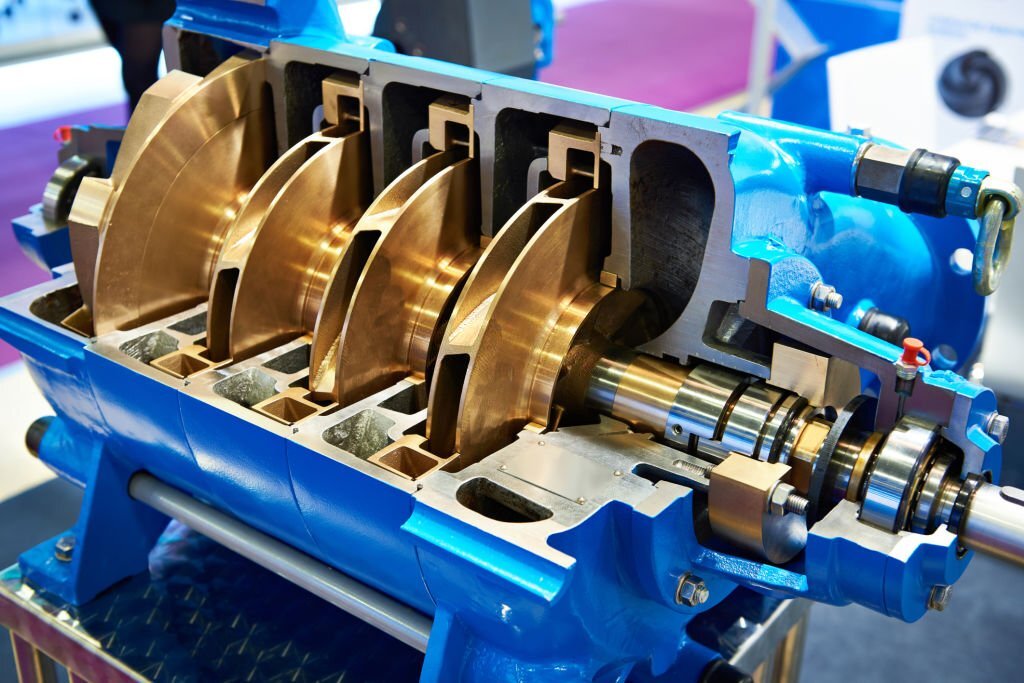

Centrifugal compressors play a vital role in several key industries, and the performance and reliability of these machines are contingent on the quality and efficiency of their parts. From the oil and gas sector to manufacturing and beyond, the impact of centrifugal compressor parts is far-reaching. In this article, we will explore the indispensable role these parts play in key industries, how they contribute to operational efficiency, and why choosing the right manufacturer, like the best centrifugal compressor parts manufacturer in Gujarat, Aashapuri Engineering, is crucial.

1. Oil and Gas Industry

In the oil and gas industry, centrifugal compressors are the workhorses that handle the compression of natural gas and other hydrocarbons. These compressors are used at various stages of the production process, from gas gathering and transportation to refining and distribution.

The critical components of a centrifugal compressor, such as impellers, casings, and bearings, must withstand extreme conditions, including high temperatures and pressures. Any failure in these components can lead to costly downtime and safety hazards.

Centrifugal compressor parts designed and manufactured with precision are essential in this industry. They ensure the safe and efficient handling of hydrocarbons, reducing the risk of leaks, emissions, and equipment failures. Additionally, well-maintained compressor parts contribute to energy savings, which is crucial in an energy-intensive sector like oil and gas.

2. Petrochemical Industry

The petrochemical industry relies heavily on centrifugal compressors for processes like ethylene and propylene production, as well as various chemical reactions. These compressors play a pivotal role in maintaining pressure and temperature conditions essential for chemical processes to occur efficiently.

Centrifugal compressor parts in the petrochemical industry must be corrosion-resistant, durable, and capable of withstanding aggressive chemicals. This highlights the importance of using high-quality materials and precision engineering in their manufacturing. Well-maintained compressors and parts help ensure the uninterrupted production of critical chemicals, contributing to the industry’s growth and stability.

3. Manufacturing Sector

In the manufacturing sector, centrifugal compressors are often used to provide a reliable source of compressed air for various applications, such as pneumatic tools, assembly line machinery, and quality control systems. The quality and efficiency of compressor parts directly impact production efficiency and product quality.

Well-designed and maintained compressor parts ensure a consistent and reliable supply of compressed air, preventing production delays and defects. Moreover, energy-efficient compressors components help reduce operational costs and environmental impact, aligning with sustainability goals in the manufacturing sector.

4. Power Generation

Centrifugal compressors are integral to power generation facilities, where they play a role in gas turbines and steam turbines. These turbines are used for electricity generation in combined cycle power plants and as mechanical drives in various industrial processes.

The reliability and efficiency of centrifugal compressor parts are critical in power generation. Any disruption in the compressor’s performance can lead to power outages or decreased efficiency, affecting electricity supply and production processes. Choosing high-quality components and conducting regular maintenance ensures the uninterrupted operation of power generation facilities.

5. Aerospace and Aviation

The aerospace and aviation industries rely on centrifugal compressors for aircraft propulsion and environmental control systems. These compressors are essential for ensuring the safety and performance of aircraft.

Centrifugal compressor parts in aviation must meet stringent quality and safety standards. Precision engineering and the use of advanced materials are vital to withstand the extreme conditions encountered during flight. Well-maintained compressors contribute to the reliability of aircraft systems, enhancing passenger safety and the operational efficiency of airlines.

6. Chemical Processing

In chemical processing plants, centrifugal compressors are used for various applications, including gas compression, gas liquefaction, and refrigeration. These compressors are integral to maintaining specific temperature and pressure conditions required for chemical reactions.

The choice of compressor parts is crucial in chemical processing due to the presence of aggressive chemicals and the need for precise control. High-quality parts ensure the integrity of chemical processes, minimize downtime, and enhance safety in chemical plants.

7. Pharmaceutical Industry

The pharmaceutical industry relies on centrifugal compressors for various processes, including air and gas compression, as well as refrigeration for temperature-sensitive materials. The quality and efficiency of compressor parts directly impact the production of pharmaceuticals.

In pharmaceutical manufacturing, maintaining strict quality standards and minimizing contamination risks are paramount. Well-designed and maintained compressors parts help ensure the consistency and purity of pharmaceutical products.

8. Food and Beverage Production

Centrifugal compressors are used in the food and beverage industry for tasks like refrigeration, air compression, and gas separation. These compressors play a role in preserving food quality, optimizing production processes, and ensuring compliance with food safety regulations.

High-quality compressor parts are essential in this industry to prevent contamination and maintain the integrity of food products. They contribute to energy-efficient refrigeration and compressed air systems, reducing operational costs.

Conclusion

Centrifugal compressor parts are the unsung heroes of various key industries, silently powering critical processes and ensuring operational efficiency. From oil and gas to manufacturing, aerospace, and beyond, these parts are the backbone of essential operations. The quality and precision of these parts have a direct impact on safety, efficiency, and environmental sustainability. Therefore, whenever you are in need of any parts of the centrifugal compressor, contact the best manufacturer of the centrifugal compressor parts in Gujarat, Aashapuri Engg.

Choosing best and experienced centrifugal compressor parts manufacturer in Gujarat, like Ashapuri Engg, is essential to ensure the longevity and performance of these vital components. As industries continue to evolve and demands for efficiency and sustainability increase, the role of high-quality centrifugal compressor parts will only become more integral in driving success across a diverse range of sectors. Therefore, you are in need of any parts of the centrifugal compressor; contact the top manufacturer of centrifugal compressor parts in Gujarat, Ashapuri Engineering.