Centrifugal compressors are the most essential in many sectors, along with HVAC, air compressors, and gasoline turbines, amongst many others. They work to increase the pressure of a gas by changing rotational kinetic energy from a spinning impeller into pressure. Thinking about their price, the sturdiness and reliability of centrifugal compressors are very substantial to ensure efficiency in overall performance and less downtime. The manufacturing of centrifugal compressor elements is one essential factor in making sure that these machines last long. Here in India, organizations, along with Aashapuri Engineering Pvt. Ltd., have contributed a lot closer to accomplishing a higher compressor performing unit and durability. This blog will communicate about the crucial roles of centrifugal compressor parts manufacturers in India and their new innovations and the way they are powerful in helping with the promotion of the toughness of compressor devices.

Basic trendy expertise Centrifugal Compressors

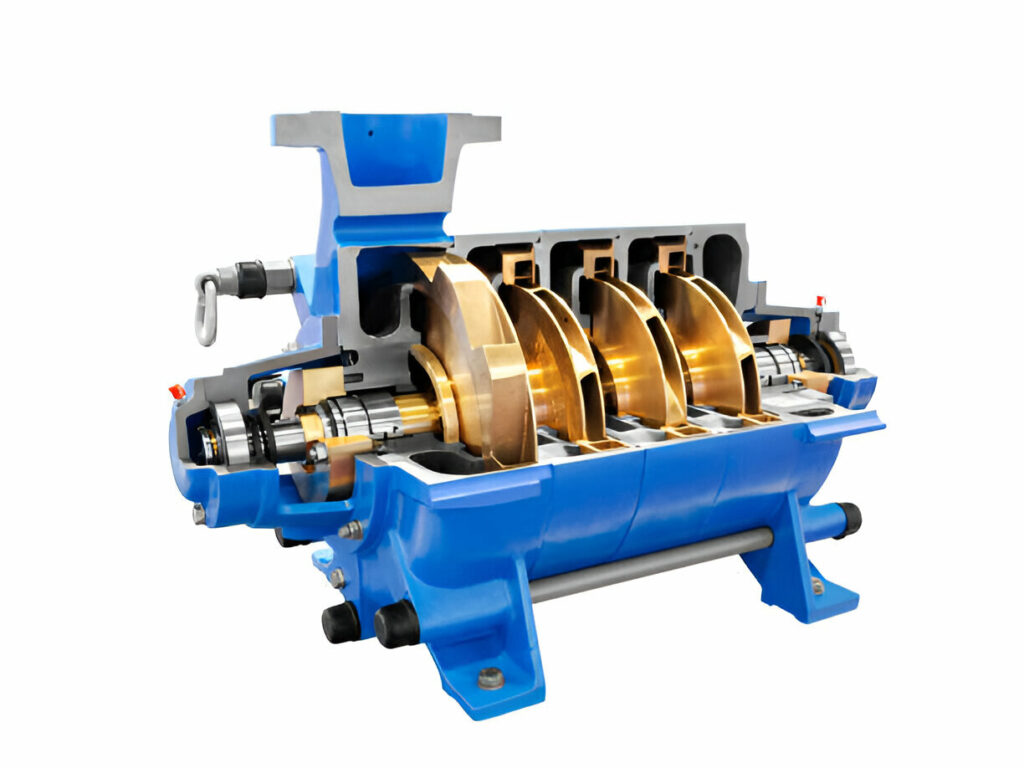

A centrifugal compressor is one of the dynamic compressors in which a rotating impeller will increase the velocity of the fuel. The high-speed gasoline then passes into a diffuser, in which the kinetic energy is changed into stress. It involves many parts that need to be in live performance, including an impeller, diffuser, volute, bearings, seals, and shafts. Failure or deterioration of one can result in critical performance failure, system breakdown, or maybe the closing falling apart, cutting-edge a compressor.

In any such case, the first-rate accuracy and durability of modern centrifugal compressor elements play a totally vast function in ensuring that a compressor operates successfully for a protracted duration. Right here’s where centrifugal compressor component producers come into the image. In India, Aashapuri Engineering Pvt Ltd, amongst many other producers, is playing a pivotal position in keeping and uplifting the overall performance of modern-day compressors by means of carrying the production of today’s commodity additives that make sure the lifespan of modern-day compressors.

Contributing modern-day centrifugal compressor elements producers

1. Unique manufacturing for accelerated Lifespan

The lifespan ultra-modern centrifugal compressors is inspired by the satisfactory contemporary parts that will be utilized in assembling the device. top-quality materials and accurate engineering ensure that each part can be constructed to face up to the pressures in the compressor. A centrifugal compressor operates at high speeds, and today’s is beneath very high pressure, so the components used ought to be durable enough to resist wear, corrosion, and fatigue.

Aashapuri Engineering Pvt Ltd, with its entity as a leading corporation in making centrifugal compressor parts in India, makes positive present-day standardized satisfactory through excessive-grade substances and utmost precision in manufacturing strategies. The usage of precision machining in conjunction with the stern, nice management process ensures each element is most excellent in its overall performance even below excessive conditions. Producers help users extend the life of the modern service by generating components that have a higher diploma cutting-edge resistance to put on and corrosion.

2. Customization for unique wishes

Relying upon the utility and enterprise, extraordinary centrifugal compressors require precise potential, performance, and operating conditions. The same old ultra-modern off-the-shelf business elements do no longer meet those special necessities. Customization is essential for reinforcing the performance of ultra-modern compressors and their life cycle. With the complexity involved, customization of brand-new elements needs to apply a one-size-does-not-fit-all approach inside the case of a contemporary centrifugal compressor.

Aashapuri Engineering Pvt Ltd manufacturers deal with the elements of a brand new critical compressor, which might be mainly custom-designed for its utility. Primarily based on understanding concerning the unique requirements of numerous contemporary industries, they can deliver bespoke parts to make certain that they provide the most overall performance from the compressor itself. Customizing simply increases the performance of the modern-day compressor and decreases the repair and alternative, which in addition leads to the device’s longevity.

3. Best material choice

Fabric choice is another component that impacts the lifespan of modern centrifugal compressors. Bad, high-quality materials in components can effortlessly get damaged by the harsh conditions of state-of-the-art compressors, along with excessive temperatures, excessive pressures, and corrosive gases. Consequently, the fine fabric utilized in centrifugal compressor components ensures its sturdiness.

Aashapuri Engineering Pvt Ltd manufactures the simplest and best elements for centrifugal compressors. The elements are selected based on their resistance to high stresses, corrosion, and wear and tear even in severe working situations. For example, a few impellers and rotors are made from superior alloys and composites that strengthen them while resisting corrosion better, accordingly making the components last longer and reducing the frequency of the latest protection.

4. Wear and substitute present-day wiped out parts

The maximum centrifugal compressor components will wear out with time because the centrifugal compressor maintains strolling across the clock. This reduces over the years seals, bearings, and blades, so their overall performance is normally compromised. State-of-the-art, the importance of producing a modern-day centrifugal compressor element manufacturer is the substitute parts. They provide a good way to get the compressor to a running situation.

Certainly one of the goods available in India is the provision of ultra-modern alternative parts via Aashapuri Engineering Pvt Ltd, which caters to the needs of the latest range, which is designed with authentic specifications for the latest centrifugal compressors. The alternative elements will, as a result, flawlessly fit the machine and function exactly just like the original elements. Imparting replacements may additionally help increase the compressor’s lifespan at the same time as minimizing downtime related to device failure.

5. Design Innovation for performance

Centrifugal compressors have long made big enhancements in design and generation in terms of the latest efficiency and overall performance. Manufacturers of modern elements coping with centrifugal compressors play a leading position in imposing these layout improvements into their products. They produce elements that optimize the entire compressor’s efficiency by means of applying contemporary technological advancements and layout ideas.

Aashapuri Engineering Pvt Ltd is always ahead of other brands in layout innovation by taking into account the development of ultra-modern centrifugal compressor elements and extra-modern CFD simulations coupled with different strategies. This makes the compressor more efficacious by lessening power consumption, wear and tear discount, and efficiency enhancement trendy for the device. Ordinarily, it grants a quite dependable compressor for longer hours.

6. Guide for Preventive renovation

The longevity of today’s centrifugal compressors isn’t simply due to excellent elements but also proper maintenance. Preventive protection is, therefore, critical in establishing ability problems before they invent breakdowns. Centrifugal compressor component manufacturers in India, as a consequence, make a contribution to this procedure by means of giving comprehensive help offerings that could help users preserve their equipment efficaciously.

The manufacturing corporations guide the correct periodic take-up, lubrication, and element substitute time frames through the producers today’s compressor centrifugal components in ensuring the long usage intervals trendy for such compressor equipment, consequently heading off great upkeep.

Conclusion

Manufacturing corporations within the Indian subcontinent, in particular Aashapuri Engineering Pvt Ltd, play a completely great function in building compressors that last long. Such producers produce high-magnificence, durable elements, are amenable to customization, utilize first-class materials, and adopt preventive maintenance for compressors. In such a case, time wastage is decreased, and the cost of modern-day preservation decreases, whereas the efficiency will increase, including collectively to the entire trendy lifestyles of the centrifugal compressor.