Types of taper lock bush—top taper lock bush manufacturer in india

In the world of industrial mechanics, even the smallest components can have a massive impact. The taper lock bush is a mechanical element that serves as the foundation of numerous systems. Whether used in power transmission, heavy-duty conveyor setups, or integrated with timing pulleys for synchronous motion, these bushings ensure tight connections, durability, and efficiency. Over time, their role has expanded, and their design has become more sophisticated to meet modern industrial demands. Among many suppliers and manufacturers, Aashapuri Engineering Pvt Ltd stands out as a trusted taper lock bush manufacturer in India, offering reliability and technical excellence. Their products are not just components; they are the lifeblood of countless rotating systems, holding together shafts and pulleys in motion with unmatched precision.

From high-torque environments to light-duty setups, Aashapuri Engineering’s taper lock bushes and pulley combinations support industrial functionality at its finest. Their products continue to establish new benchmarks, whether for precision-driven automation or large-scale manufacturing facilities. In this article, we explore the various types of taper lock bushes, their real-world applications, and what sets Aashapuri Engineering apart as a leading taper lock bush with timing pulley manufacturer in India.

The purpose and power of a taper lock bush

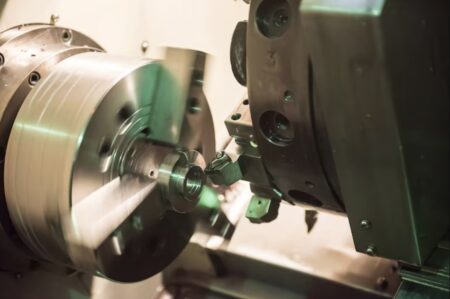

The concept behind the taper lock bush is relatively straightforward. It is a cone-shaped mechanical device used to connect pulleys, sprockets, and couplings with shafts. By tightening screws, the bush contracts onto the shaft, securing the element in place. This method provides two significant advantages: ease of installation and precision alignment. Compared to older keyway or press-fit systems, taper lock bushes require less downtime and offer better long-term performance.

Moreover, their universal design allows them to be compatible with various shaft sizes and mechanical systems. They can be easily removed and replaced without damaging the equipment, making them a popular choice for maintenance-heavy industries.

Evolution of the taper lock bush design

Initially, taper lock bushes were simple machined metal cones. Over the years, with improvements in metallurgy, machining techniques, and quality control, their designs evolved to accommodate higher speeds, greater loads, and more demanding industrial conditions.

Modern taper lock bushes from companies like Aashapuri Engineering now feature precision-machined surfaces, stress-relieved alloys, anti-corrosion coatings, and tighter tolerances. These features extend the component’s life and enhance the performance of the entire assembly.

Types of taper lock bushes and their functional characteristics

Let us now dive deeper into the different types of taper lock bushes available today. Each type has unique characteristics designed to serve specific mechanical requirements.

1. Standard Taper Lock Bushes

These are the most commonly used bushings; they are easily available in a wide range of sizes and taper dimensions. They are ideal for general mechanical assemblies, including conveyor drives, mixers, and ventilation systems. Aashapuri Engineering offers them in various materials, including cast iron, steel, and phosphor bronze, depending on load requirements.

2. QD (Quick Detachable) Bushes

QD bushings offer fast installation and removal thanks to their flange and taper design. The flange holds the component securely, and the taper ensures a firm grip. They are particularly useful when maintenance frequency is high or when quick part replacement is essential to avoid production delays.

3. Split Taper Bushes

Split taper bushes offer an enhanced grip and more uniform tightening. Because the split runs through both the taper and flange, these bushings grip the shaft more securely, ensuring minimal slippage even in high-torque settings. They are ideal for heavy-duty operations such as crushers, mills, and other large machines.

4. Weld-On Hubs

Applications that require an unbreakable mechanical bond typically use weld-on hubs, a more permanent solution. These are directly welded to the rotating component and then fitted with a standard taper lock bush. This hybrid approach combines permanence with serviceability.

5. Custom Taper Lock Bushes

Not all industries can work with off-the-shelf solutions. That is why Aashapuri Engineering also manufactures taper lock bushes tailored to client-specific requirements. Whether it involves unique materials, odd dimensions, or specialized load handling, custom solutions bring engineering precision to otherwise unconventional applications.

Material Matters: Choosing the Right Metal

Taper lock bushes are often exposed to heat, vibration, torque, and corrosion. That is why material selection is crucial. Aashapuri Engineering Pvt Ltd ensures the right balance between durability, cost, and application-specific performance. Their taper lock bushes are available in

- High-grade cast iron for general applications

- Carbon steel for added strength

- Alloy steel for extreme torque environments

- Phosphor bronze or stainless steel for high corrosion resistance

Each material brings its advantages, and depending on the use case, engineers from Aashapuri recommend the most suitable combination.

Real-World Applications of Taper Lock Bushes

The real test of a mechanical component lies in how it performs under real-world conditions. Taper lock bushes have become indispensable in various industrial sectors.

1. Manufacturing Industry

In assembly lines, taper lock bushes allow pulleys and sprockets to rotate in precise alignment with minimal vibration. This process ensures production remains smooth, fast, and uninterrupted.

2. Agricultural Equipment

From harvesters to irrigation pumps, taper lock bushes help connect shafts, pulleys, and gearboxes, ensuring durability even in dusty, wet, or rugged outdoor conditions.

3. Food Processing Plants

Due to the need for hygiene and corrosion resistance, stainless steel taper lock bushes are used in food mixers, slicers, and conveyor systems.

4. Mining and Heavy Machinery

Split taper bushes with enhanced gripping power are often used in crushing machines, conveyor belts, and hoisting mechanisms due to their load-handling capabilities.

5. HVAC Systems

Blowers and fans often rely on quick-detach bushings that allow easy replacement without dismantling the entire unit, minimizing service disruption.

Integration with Timing Pulleys

An emerging trend in precision engineering is the integration of taper lock bushes with timing pulleys. Timing pulleys are used where precise motion is required, such as in robotics, automation, and synchronous belt-driven systems. When paired with a taper lock bush, they not only ensure a strong grip on the shaft but also maintain synchronization without backlash.

Aashapuri Engineering specializes in providing pre-assembled taper lock bushes with timing pulley units, ensuring accurate torque transmission and smoother machine operation. Their advanced CNC manufacturing and in-house quality testing ensure dimensional accuracy and long-term reliability in these integrated systems.

How Aashapuri Engineering Delivers Excellence

There are countless manufacturers of mechanical components in India, but only a few companies consistently rise above expectations. Aashapuri Engineering Pvt Ltd has built its reputation not just by manufacturing components but by delivering reliability and building trust. Here is what makes them an industry leader:

1. Advanced Manufacturing Infrastructure

Their in-house CNC facilities, precision casting equipment, and automated quality control systems ensure that every bush, hub, and pulley meets industry standards for accuracy and performance.

2. Industry Certifications

Aashapuri Engineering follows strict quality control processes aligned with national and international standards. This approach ensures compatibility with industrial equipment used globally.

3. Versatile Supply Chain

Their distribution network is strong enough to cater to both domestic and international markets. Whether a client requires a few hundred pieces or a bulk OEM supply, delivery timelines are streamlined without compromising quality.

4. Dedicated Engineering Support

Unlike generic suppliers, Aashapuri offers pre-sale and post-sale support. Their team of engineers helps clients select the right type of bush, assists in integration, and provides custom design modifications when needed.

Maintenance and Longevity: How to Maximize the Life of Your Bush

Installing a high-quality taper lock bush is only half the journey. To ensure it delivers long-term performance, proper installation and periodic maintenance are essential. Here are some tips often recommended by Aashapuri’s engineers:

- Use proper torque during installation to avoid overtightening or undertightening, both of which can lead to premature failure.

- Apply anti-seize compound between the bushing and pulley to make future disassembly easier.

- Perform periodic alignment checks on high-speed applications to avoid shaft wear or imbalance.

- Clean the bore and shaft before every reinstallation to prevent particle-induced wear.

By following these simple yet effective practices, one can extend the life of both the bush and the mechanical component it supports.

Looking Ahead: The Future of Taper Lock Bushes in Modern Engineering

As industries become smarter and more automated, the role of machine components like taper lock bushes will continue to evolve. With the rise of predictive maintenance and high-speed automation, demand for zero-tolerance, high-precision components is rising. Aashapuri Engineering is not just keeping up with this trend—it is leading it.

Their investment in R&D, adoption of smart manufacturing techniques, and focus on customer-centric innovation ensure that they will continue to be a go-to partner for companies requiring trustworthy taper lock bush systems.

Summary

Taper lock bushes may seem like minor components in a mechanical system, but their function is foundational. From driving heavy machinery in the mining sector to maintaining precise motion in automation setups, these elements carry the responsibility of reliability, grip, and synchronization.

In this detailed blog, we explored:

- The various types of taper lock bushes include standard, split, QD, weld-on, and custom variants.

- Their applications are across industries like manufacturing, mining, agriculture, and food processing.

- Material choices that determine longevity and performance.

- The rising importance of taper lock bushings with timing pulley integration for precision applications.

- The advantages of sourcing from a reputed manufacturer like Aashapuri Engineering Pvt Ltd.

Aashapuri Engineering Pvt Ltd, with its decades of experience, future-ready production line, and unwavering commitment to client satisfaction, remains a leading taper lock bush manufacturer in India. Whether one requires standard mechanical fittings or advanced integration with synchronous drives, Aashapuri delivers value that goes beyond metal and measurements.

For superior reliability and seamless industrial performance, explore the precision-engineered range of taper lock bush systems from Aashapuri Engineering Pvt. Ltd. today.