Centrifugal pump shaft alignment and why is it necessary in India?

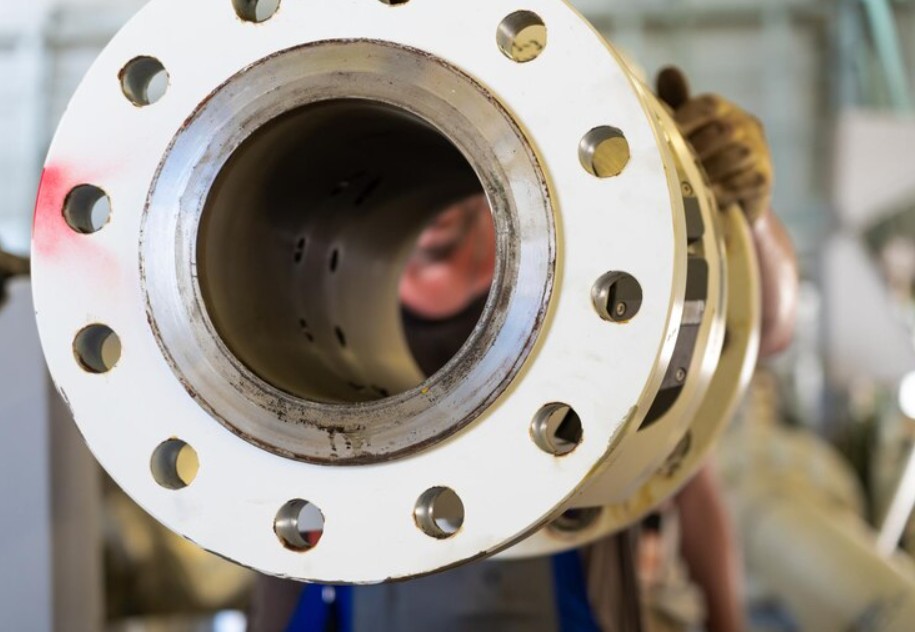

Centrifugal pumps play a crucial role in various industries, ranging from water treatment and power plants to manufacturing and oil & gas. One of the most vital components in centrifugal pumps is the shaft, which connects the impeller to the motor. The shaft must be aligned correctly to ensure the pump operates efficiently and with minimal wear and tear. In India, where industries depend heavily on centrifugal pumps for a variety of processes, the importance of shaft alignment cannot be overstated. As a leading centrifugal pump shaft manufacturer in India, Aashapuri Engineering Pvt. Ltd. understands the significance of precision and the role proper alignment plays in the longevity and efficiency of a pump. Shaft misalignment can lead to a range of problems, including excessive vibration, heat generation, and premature failure of components. This is why regular and accurate centrifugal pump shaft alignment is essential to maintain optimal pump performance and avoid costly repairs or downtime. Moreover, the introduction of centrifugal pump shaft sleeves by manufacturers like Aashapuri Engineering Pvt. Ltd. ensures that these components are well protected from wear and corrosion, further enhancing their lifespan and reducing the frequency of maintenance.

The Mechanics of Centrifugal Pump Shaft Alignment

A centrifugal pump works by converting rotational energy into fluid flow, powered by the shaft, which is driven by an electric motor or engine. When the shaft is not aligned correctly with the motor, the pump suffers from vibrations, energy inefficiencies, and increased friction. This misalignment, whether caused by wear, improper installation, or damage, leads to significant operational issues. Vibration is one of the most common signs of shaft misalignment. If left unchecked, it can cause damage to bearings, seals, and other internal components, significantly reducing the pump’s lifespan.

Alignment of the centrifugal pump shaft is typically achieved through precise measurement tools and techniques. The process involves ensuring that the motor shaft and the pump shaft are perfectly parallel. Inaccurate alignment leads to uneven distribution of stress on the shaft, causing irregular wear and potential failure of the pump’s mechanical components. In India, the industrial landscape often faces unique challenges such as high temperatures, fluctuating loads, and rough operating conditions that make proper shaft alignment even more critical for maintaining pump efficiency.

Types of Shaft Misalignment in Centrifugal Pumps

Several types of misalignment can affect centrifugal pump shafts. The most common ones include angular misalignment, parallel misalignment, and a combination of both.

- Angular misalignment occurs when the shafts of the pump and motor are not aligned in the same angle. This causes uneven loading on the bearings, leading to faster wear and tear.

- Parallel Misalignment happens when the shafts are not aligned horizontally or vertically. Even small misalignments can lead to excessive bearing loads and vibrations, which can damage other parts of the pump.

- Coupled misalignment is a combination of both angular and parallel misalignment, causing more complex issues and often resulting in more severe damage to the pump system.

Each type of misalignment requires careful adjustment and correction. For industries that rely heavily on centrifugal pumps, such as water supply and treatment plants, chemical processing plants, and HVAC systems, addressing these misalignments is essential for preventing unnecessary damage and operational inefficiencies.

Why Shaft Alignment Is Particularly Important in India

In India, industries are facing growing demands for higher production rates and greater operational efficiency, often under challenging environmental conditions. Factors such as the availability of skilled labor, maintenance resources, and the operating environments of industries require pumps that perform optimally for longer periods.

Given that India has a vast and diverse industrial sector—spanning agriculture, textiles, chemicals, food processing, power generation, and more—centrifugal pumps are used extensively in a wide variety of applications. In this context, the need for centrifugal pump shaft sleeve manufacturers in India like Aashapuri Engineering Pvt. Ltd. becomes evident. By manufacturing high-quality shaft sleeves, companies can prevent the common wear and tear associated with shaft misalignment. These sleeves act as a protective layer against corrosion and erosion, ensuring that the pump’s shaft remains in top working condition for a more extended period. This is particularly important in industries where pumps are exposed to harsh chemicals, extreme temperatures, and heavy usage.

The Impact of Misalignment on Centrifugal Pumps in Indian Industries

When a centrifugal pump is misaligned, the consequences can be severe. The most immediate effect is increased vibration, which often leads to mechanical damage. Bearings, seals, and even the motor itself can be compromised if the problem persists. Vibration not only causes mechanical issues but also increases noise levels, which is undesirable in many industrial settings.

Furthermore, misalignment leads to energy inefficiencies. The misaligned shaft forces the pump to work harder to maintain the same flow rates, consuming more power than necessary. This can result in higher energy costs and reduced operational efficiency, further impacting the bottom line of businesses.

In the long term, continued misalignment results in premature pump failure. If left unaddressed, it can cause the pump to seize completely, leading to expensive repairs and unplanned downtime. In industries that rely on continuous processes—such as power generation, oil and gas, and pharmaceuticals—downtime is particularly costly. Therefore, regular maintenance, including proper shaft alignment, is essential for ensuring that pumps continue to perform at their best without sudden interruptions.

Best Practices for Centrifugal Pump Shaft Alignment

To avoid the negative impacts of shaft misalignment, it is essential to follow best practices when installing and maintaining centrifugal pumps. Some key steps to achieving proper shaft alignment include

- Routine Inspections: Regularly inspect the alignment of the pump shaft, especially after installation or repairs. This ensures that any misalignment issues are detected early.

- Use Precision Instruments: High-quality measuring instruments such as laser alignment tools are crucial for achieving precise alignment. These tools allow for more accurate adjustments and reduce the chances of errors during the alignment process.

- Monitor Vibration: Vibration monitoring systems can help detect early signs of misalignment. These systems can measure vibration frequency and amplitude to provide real-time data on the pump’s performance.

- Alignment Tolerances: Always follow the manufacturer’s specifications for alignment tolerances. These tolerances will vary depending on the size and type of centrifugal pump and must be adhered to for optimal performance.

- Use of Shaft Sleeves: Using high-quality shaft sleeves can protect the pump shaft from wear and corrosion caused by misalignment. These sleeves are a cost-effective way to extend the life of the pump and improve its overall reliability.

The Role of Aashapuri Engineering Pvt Ltd in Ensuring Proper Shaft Alignment

Aashapuri Engineering Pvt Ltd, a leading centrifugal pump shaft manufacturer in India, specializes in the design, manufacturing, and supply of high-quality pump shafts and shaft sleeves. By offering precision-engineered products, Aashapuri Engineering ensures that centrifugal pumps function efficiently and remain reliable over long periods. With a focus on quality and durability, Aashapuri’s products help prevent the issues that arise from improper shaft alignment.

As an industry leader, Aashapuri Engineering also provides valuable insights into proper installation practices and offers regular maintenance and repair services to ensure that pumps continue to operate at peak efficiency. Their expertise in centrifugal pump systems makes them a trusted partner for industries across India, from water treatment plants to chemical manufacturing units.

Why Choose Aashapuri Engineering Pvt Ltd for Centrifugal Pump Shaft Solutions?

Choosing the right centrifugal pump shaft sleeve manufacturer in India is critical to the performance of the pump. Aashapuri Engineering Pvt Ltd offers unmatched quality, reliability, and customer support, making them a preferred choice for many industries in India. Their products are designed to withstand the harsh conditions found in industrial environments, ensuring long-term reliability and minimal downtime.

Aashapuri Engineering’s commitment to precision engineering ensures that each centrifugal pump shaft and sleeve is crafted to meet the highest standards. This focus on quality and customer satisfaction makes them a trusted name in the centrifugal pump manufacturing industry.

Conclusion

Proper centrifugal pump shaft alignment is crucial for ensuring the long-term efficiency, reliability, and performance of centrifugal pumps in India. Misalignment can lead to a host of problems, including excessive wear, vibration, and energy inefficiency. By utilizing the products and services offered by Aashapuri Engineering Pvt Ltd, industries across India can protect their centrifugal pumps and ensure optimal performance. Regular alignment checks, the use of high-quality shaft sleeves, and adherence to best practices are key steps in preventing pump failure and reducing maintenance costs. For industries looking to improve the performance and lifespan of their centrifugal pumps, Aashapuri Engineering Pvt Ltd is the trusted partner to rely on.

If you are looking for precision-engineered centrifugal pump shafts and sleeves, contact Aashapuri Engineering Pvt Ltd today for all your centrifugal pump needs. Their expert team is ready to help you ensure the reliability and efficiency of your pump systems.